A Detailed Guide On How To Cut Tile Trim

Tile trims function as vital components in tiling projects because they deliver both useful and visual advantages. Tile edges receive protection from damage through trims while they create a polished finish and help surfaces meet each other smoothly. Metal tile trims made from stainless steel and aluminum represent among the most popular trim options because they deliver excellent durability and resistance to corrosion together with contemporary design appeal. The guide provides complete instructions for metal tile trim cutting to help professionals achieve top-notch tiling results when working on bathroom tile trim, kitchen tile trim and floor tile trim.

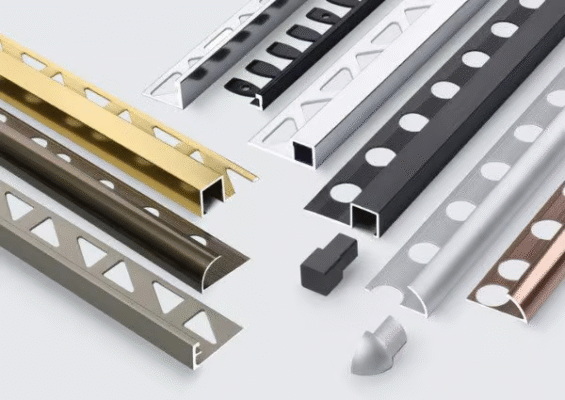

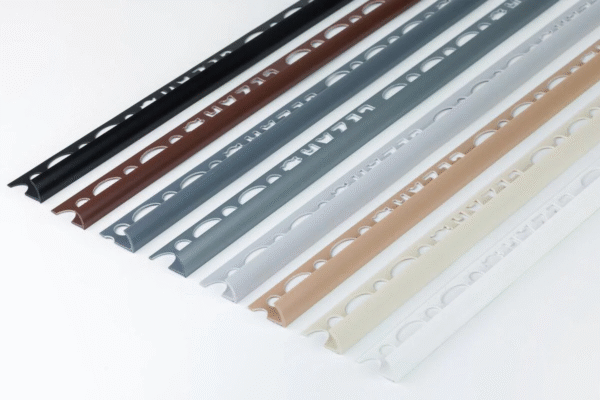

Types of Tile Trims

The selection of suitable tile trim determines both design quality and operational functionality. The table shows the main types of tile trims that customers can select from.

|

Material |

Description |

Applications |

|---|---|---|

|

Metal Tile Trim (Stainless Steel, Aluminum) |

Highly durable and corrosion-resistant, available in finishes like chrome tile trim, brass tile trim, gold tile trim, and black tile trim. |

High-traffic areas, bathroom tile trim, kitchen tile trim, tile trim for external corners. |

|

PVC Tile Trim |

Lightweight, cost-effective, available in various tile trim colors like white tile trim and grey tile trim. |

Budget-conscious projects, domestic spaces. |

|

Ceramic or Stone Tile Trim |

Matches tile material for a seamless look, but fragile and requires careful handling. |

Aesthetic-focused projects, tile trim for metro tiles. |

Stainless steel tile trim together with aluminum tile trim remains the top choice for projects needing durability and modern appearance because they work well with sizes like tile trim 10mm, tile trim 12mm, and tile trim 8mm.

Essential Tools for Cutting Tile Trims

Specialized tools exist to achieve precise cuts of tile trims depending on the material type. The following list contains basic tools required to cut metal tile trims together with PVC tile trims and ceramic tile trims:

Tool | Description |

Miter Saw | Ideal for precise straight and angled cuts, especially for metal tile trims. Use a fine-toothed blade for clean results. |

Hacksaw | Suitable for smaller projects or when a miter saw is unavailable. Use a metal-cutting blade for stainless steel tile trim. |

Tin Snips | Perfect for cutting curves in aluminum tile trim, especially for tile trim corners. |

Angle Grinder | Effective for metal tile trims with a diamond cutting disc for clean, efficient cuts. |

Tape Measure | Ensures precise measurement of tile trim lengths. |

Pencil or Marking Pen | Used to mark clear cutting lines on the tile trim. |

Clamps | Secure the tile trim during cutting to ensure cutting accuracy. |

Safety Gear | Includes safety goggles, cut-resistant gloves, and a dust mask to protect against debris and sharp edges. |

File and Sandpaper | Essential for smoothing edges after cutting to prevent injuries and ensure a professional finish. |

Mitre Block | Used with a hand saw for precise 45° angle cuts, ideal for tile trim corners. |

Step-by-Step Guide to Cutting Tile Trims

To achieve professional tile trim installations you should follow these instructions for precise tile trim cutting.

1.Precise Measurement: Use a tape measure to determine the exact length required for the tile trim, accounting for grout lines and overlaps. Verify all measurements twice because incorrect measurements may lead to misfits in 10mm tile trims and other tile trim sizes.

2.Mark the Cutting Line: Use a pencil or marking pen to mark the cutting line. Mark tile trim corners at 45° using a tile trim mitre block to obtain a perfect mitered fit.

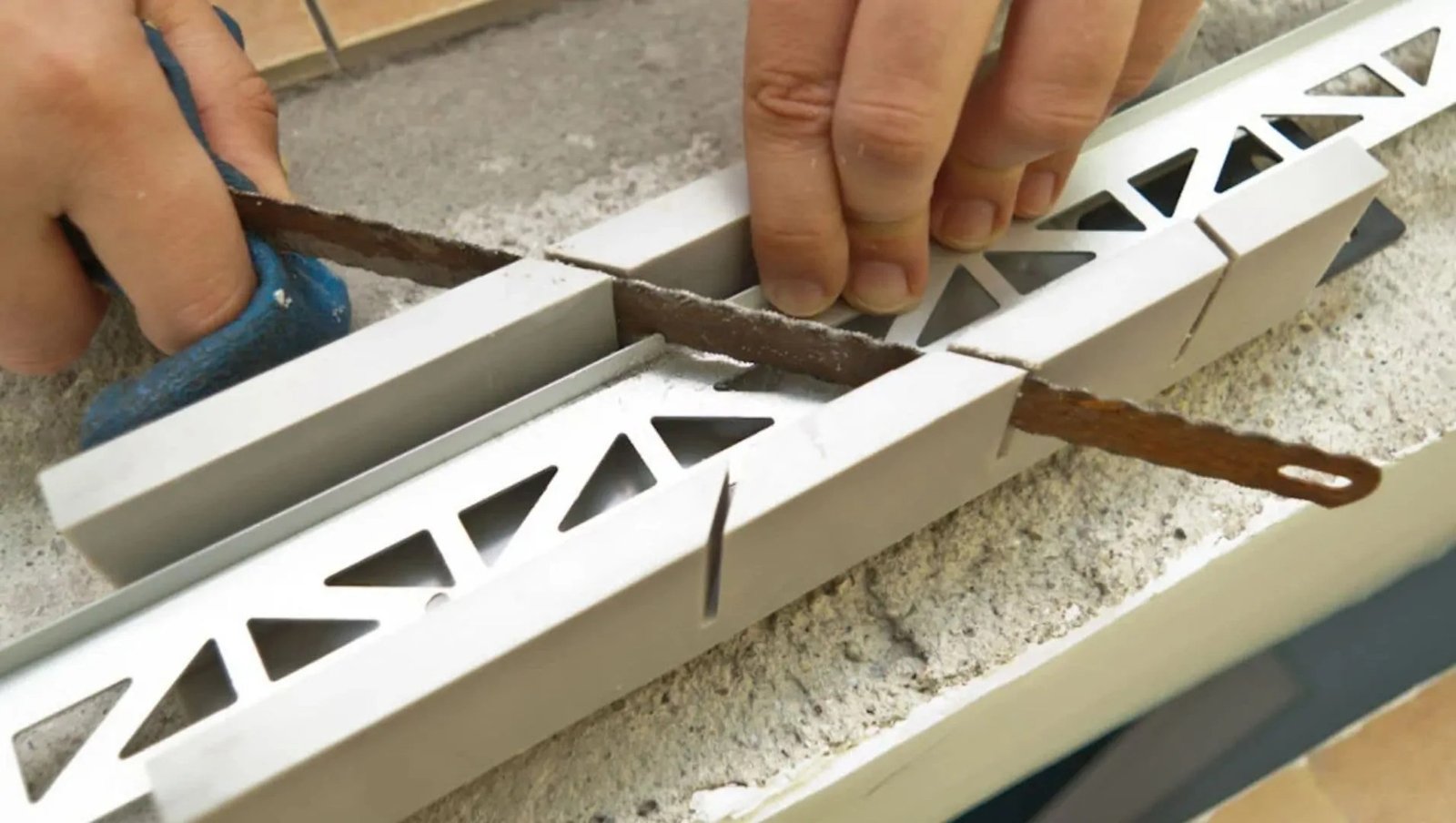

3.Secure Fixing Ensures Cutting Accuracy: Use clamps to firmly secure the tile trim to a workbench which stops it from moving and maintains precise cuts.

4.Select Specialized Tools Based on Material: Choose the tool based on the material and cut type:

- The recommended tools for straight cuts on metal tile trims include miter saws, hacksaws and angle grinders.

- The miter saw and tile trim mitre box set should be used for angled cuts with a 45° angle setting.

- A diamond edge tin snip is the recommended tool for curved cuts on aluminum tile trim.

5.Perform the Cut:

- Insert the tile trim into the miter saw using the desired cutting angle while smoothly moving it through the blade.

- Steady pressure should be maintained while cutting stainless steel tile trim with a hacksaw or angle grinder to prevent warping.

6.Smooth Edges After Cutting: After cutting metal tile trims, use a file or sandpaper to smooth out the edges for safety reasons and to achieve a professional finish.

7.Trial Fitting is Key to Professional Installation: Check the cut tile trim for proper fit before installation by making any necessary adjustments for external or internal corners.

Professional Tips for Cutting Tile Trims

These professional tips for how to fit tile trim will help you to improve your cutting process and achieve better results.

- Cutting oil should be used with stainless steel because it helps to reduce the friction and heat generation during the cutting process which results in smooth cuts.

- The tin snip is the recommended tool for making straight or curved cuts in aluminum tile trim because it provides both flexibility and precision.

- The miter saw and hacksaw blades must be kept sharp to prevent the tile trim from tearing or getting damaged.

- Ceramic tile trim should be cut using a wet saw to reduce dust production and avoid cracking.

- The selection of metal tile trims made from chrome, brass or gold is recommended because they are easier to cut and more durable.

- When cutting stainless steel tile trim it is recommended to pause the process and cool the blade by immersing it in water or pausing to prevent blade overheating.

Safety Precautions

The cutting process of tile trims requires essential safety equipment especially when metal tile trims are involved. The following precautions should be taken.

- Safety goggles should be worn to protect the eyes from debris and metal shavings.

- The use of cut-resistant gloves is recommended to protect hands from sharp edges while working with stainless steel tile trim.

- A well-ventilated area or a dust mask should be used to protect oneself from breathing in small particles.

- All tools including the miter saw and hacksaw should be in good condition to reduce the chance of accidents.

Common Mistakes to Avoid

|

Mistake |

Impact |

Solution |

|---|---|---|

|

Ignoring grout lines in measurements |

Incorrect tile trim length |

Include grout lines in precise measurements |

|

Skipping trial fitting |

Misalignment at tile trim corners |

Perform trial fitting before final installation |

|

Using incorrect tools |

Uneven cuts or material damage |

Select specialized tools based on material |

|

Cutting too quickly |

Warped or inaccurate cuts |

Use steady, controlled cutting motions |

Frequently Asked Questions

- What is the best tool for cutting stainless steel tile trim?

The recommended tools for cutting stainless steel tile trim are a miter saw with a fine-toothed blade or an angle grinder with a diamond cutting disc because they provide precise cuts and handle tough materials well.

- How can I prevent PVC tile trim from cracking during cutting?

Cut the PVC tile trim using a sharp blade while scoring it first with a marking pen to prevent cracking.

- What tool is best for cutting curves in metal tile trim?

The use of tin snips is recommended when making curves in aluminum tile trim because they provide flexibility and precision.

- What method should be used to achieve a precise 45° angle when cutting tile trim corners?

A miter saw set to a 45° angle or a tile trim mitre box with a hand saw should be used to achieve accurate cuts.

Installation Tips for Tile Trims

Cut tile trims become more effective when properly installed.

- The surface should be both clean and dry before applying adhesive.

- The tile trim requires adhesive material that matches both the installation surface and the stainless steel or aluminum trim material.

- Apply force to the tile trim until it reaches proper position while immediately removing any surplus adhesive.

- The manufacturer's guidelines determine when to proceed with tiling after the adhesive reaches its setting point.

Conclusion

The ability to cut tile trim effectively becomes vital for creating high-quality durable finishes during tiling work. The step-by-step guide provides the necessary tools to achieve accurate cuts that result in expert tile trim installations for bathroom applications as well as kitchen applications and floor applications. Modern tiling projects benefit from stainless steel tile trim and aluminum tile trim because they provide exceptional durability alongside beautiful design elements.

Our Products

Latest Articles

Get A Free Sample

Try out the products you are interested in and get free samples. See the quality for yourself and let’s start working together right away.

Get In Touch Today

After you fill out the form, We will contact you within 24 hours.

The first objective will be to understand your needs, then develop a business plan together and provide you with the best pricing!

Address

Workshop No. 3 (Self - designated), Sizhong Industrial Zone, Dazhen Community, Dali Town, Nanhai District, Foshan City

Tel

+86 13392243769

+86 13392243769

senmry@vip.163.com