How to anodizing aluminum tile trim

What is Anodizing?

The electrolytic passivation procedure of anodizing enhances the natural aluminum oxide layer by making it thicker. A process begins with submerging the metal into an acid solution while applying electrical current which results in durable aluminum oxide finishes on the surface.

Key Benefits at a Glance:

- Durability: The surface hardness of anodized materials increases because this process creates resistance to scratches and wear.

- Corrosion Resistance: The protective oxide layer functions as a barrier against moisture and chemicals in humid conditions.

- Aesthetics: The procedure enables users to customize both the color choices and finish outcomes.

- Eco-Friendliness: The non-toxic method results in recyclable materials.

- Maintenance: The finish remains simple to maintain and extends its operational period.

Core Steps for Anodizing Aluminum Tile Trim

The aluminum tile trim anodizing procedure consists of four essential steps that result in exceptional finish quality:

- Pre-Preparation and Cleaning: Before anodizing begins the aluminum tile trim requires complete cleaning for removing oils and contaminants and residues. Degreasers and alkaline cleaners should precede etching with sodium hydroxide to produce a smooth surface. The acid desmutting process cleans out every remaining contamination from the surface. The proper formation of oxide requires this fundamental step.

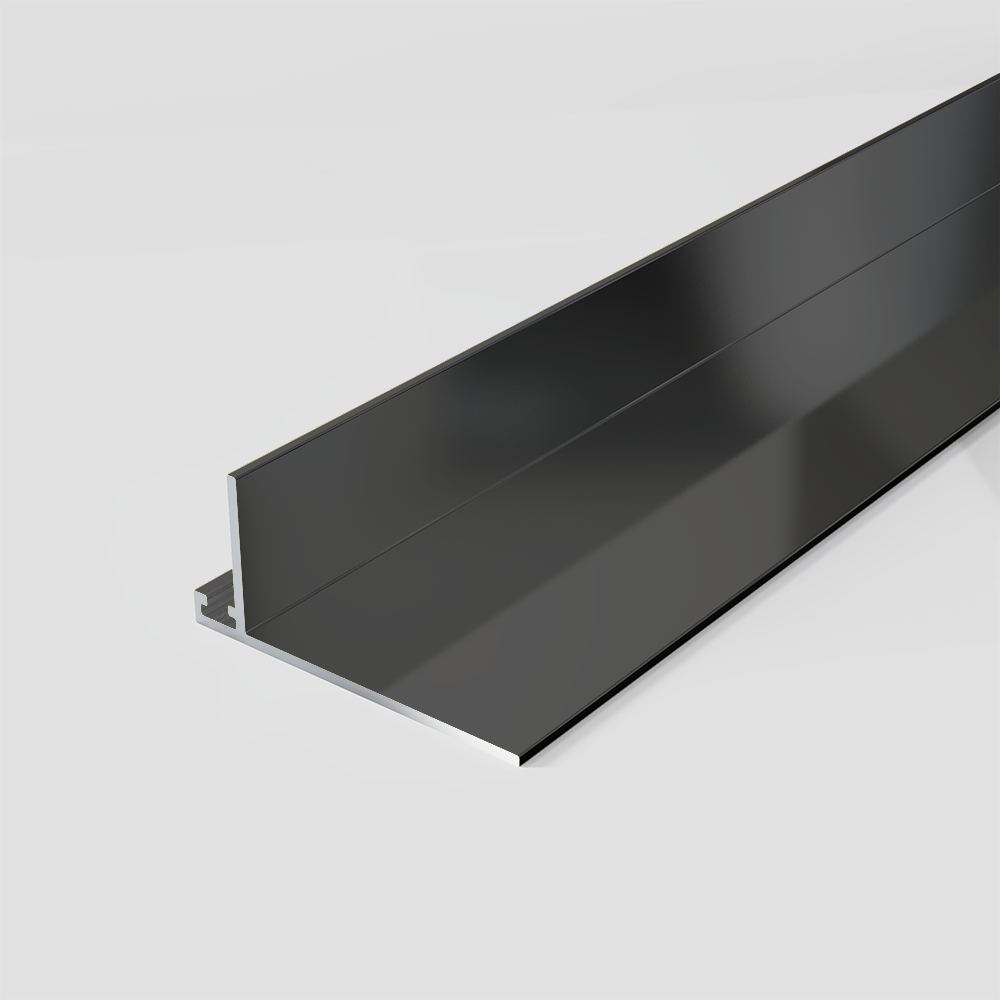

- Key Reactions in the Electrolyte: Submerge the cleaned trim in a sulfuric acid bath. The direct current must be applied through the anode with the trim as its contact point. The reaction between oxygen ions and aluminum material produces a porous oxide layer through their interaction. The desired thickness range for tile trim is achieved by managing temperature and current density during the process which results in 5-25 microns of thickness.

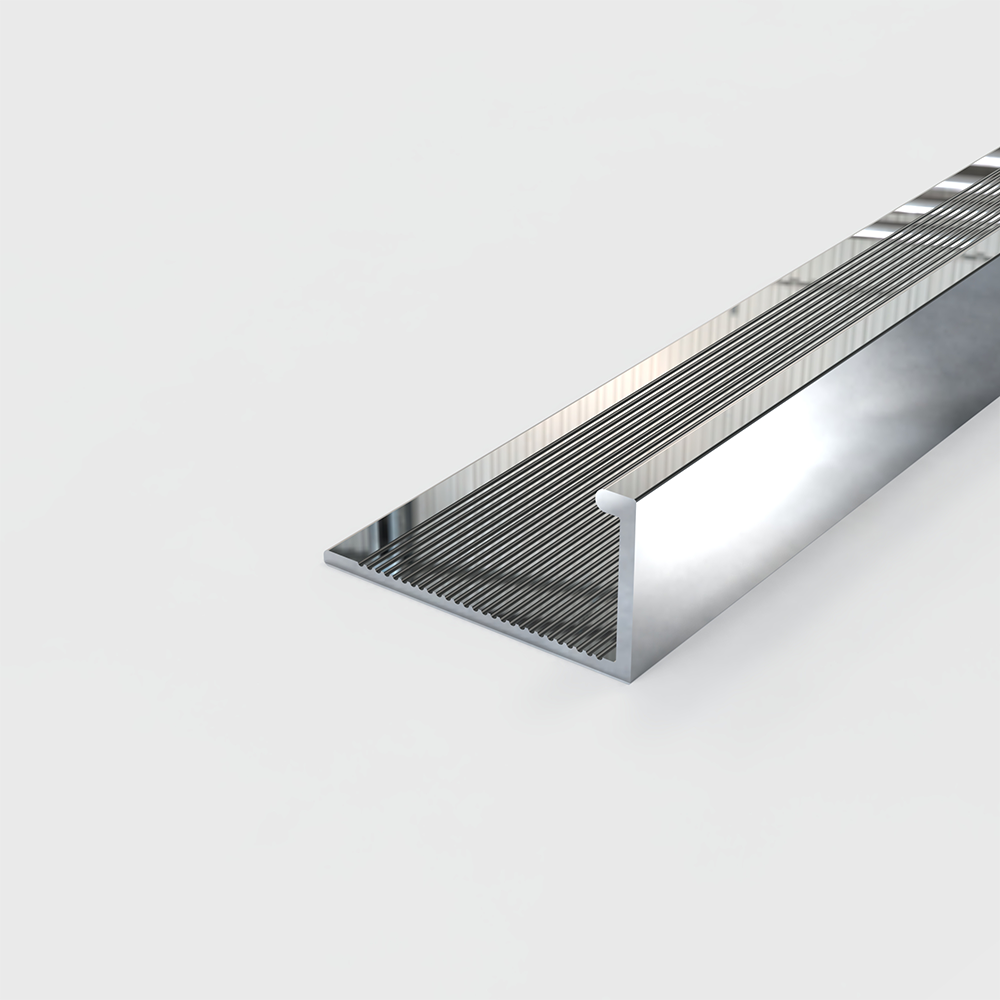

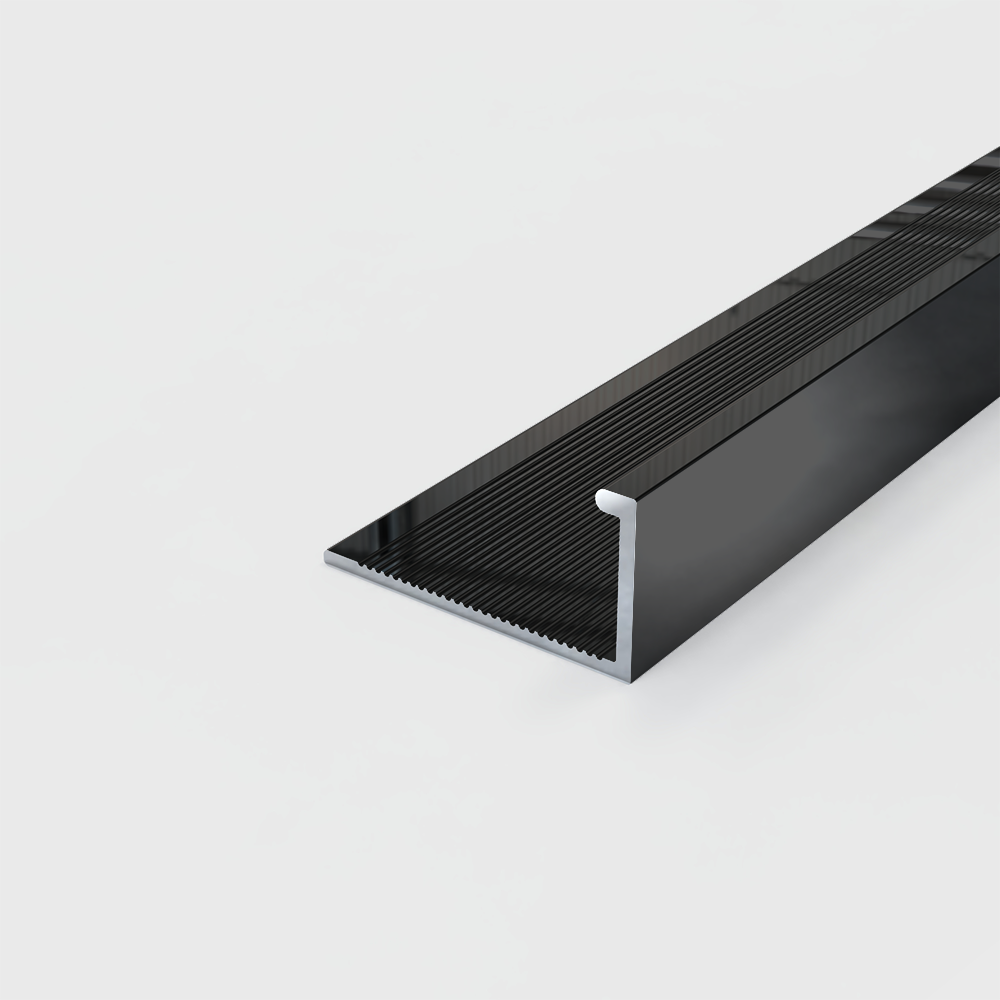

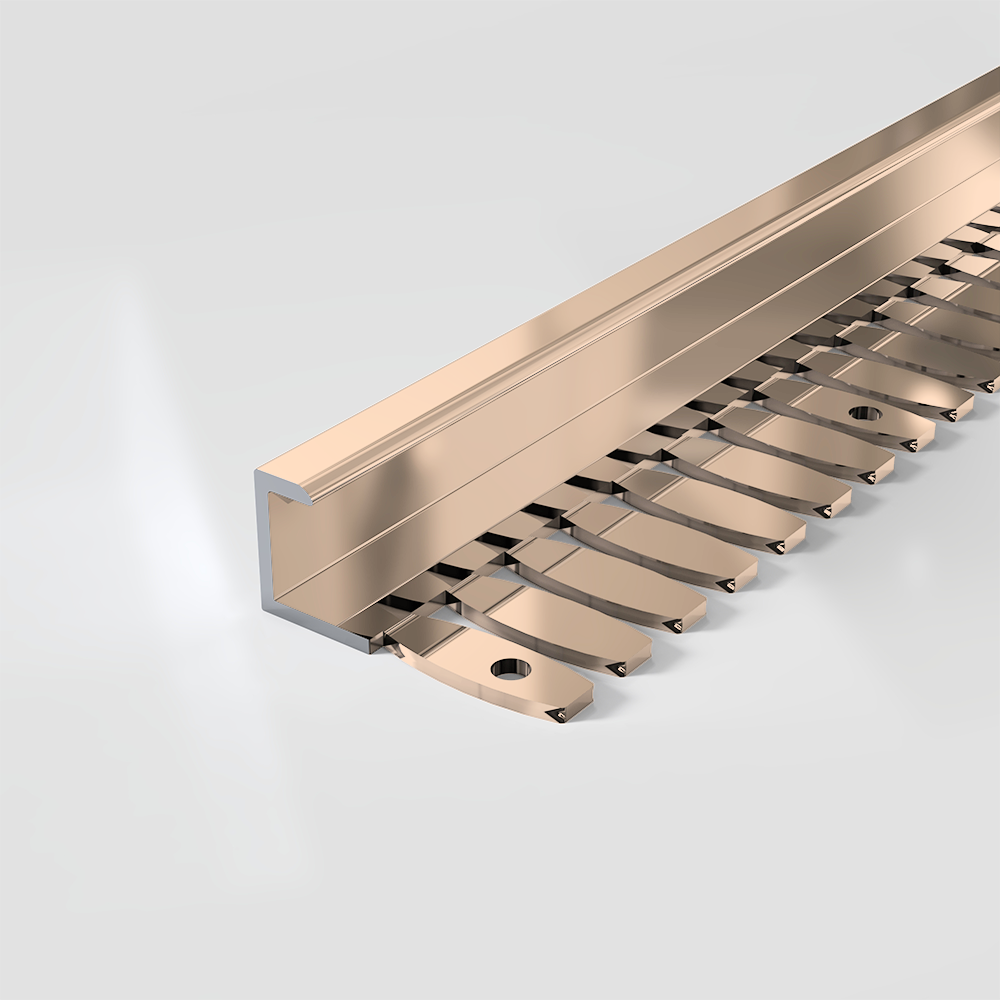

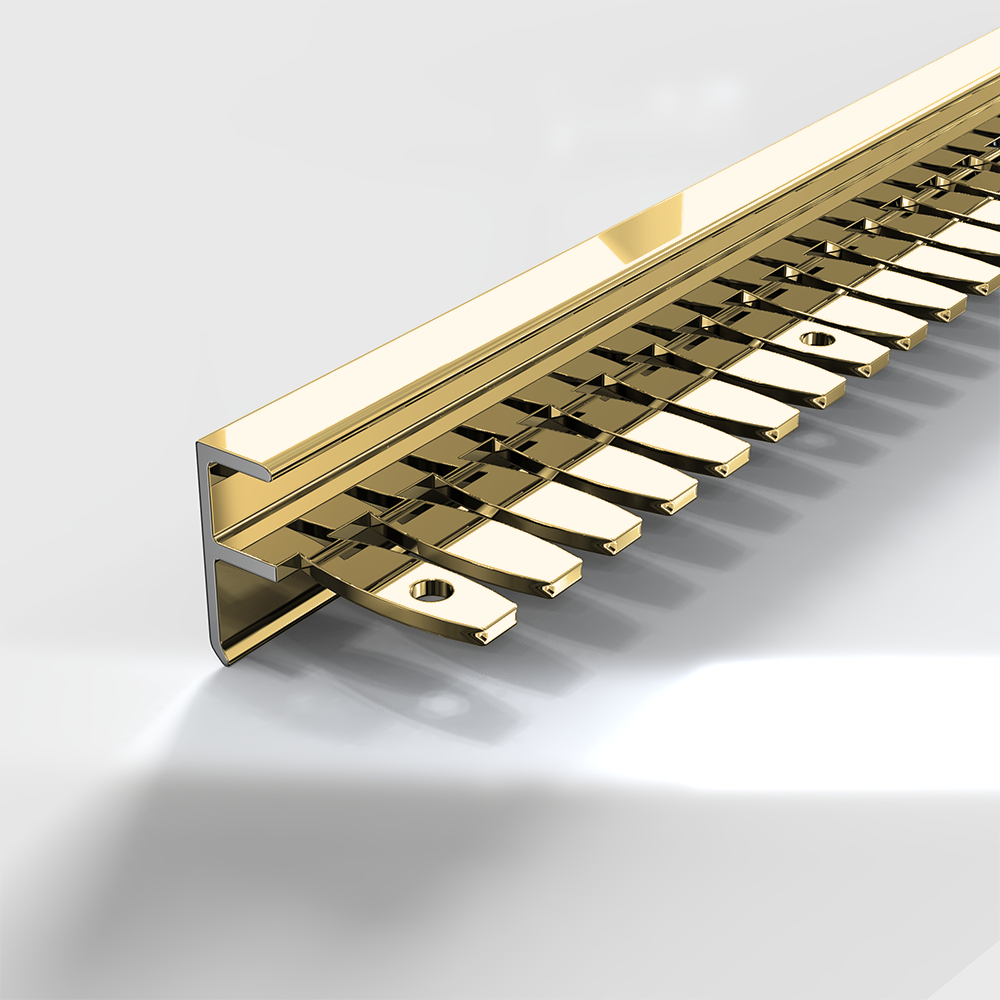

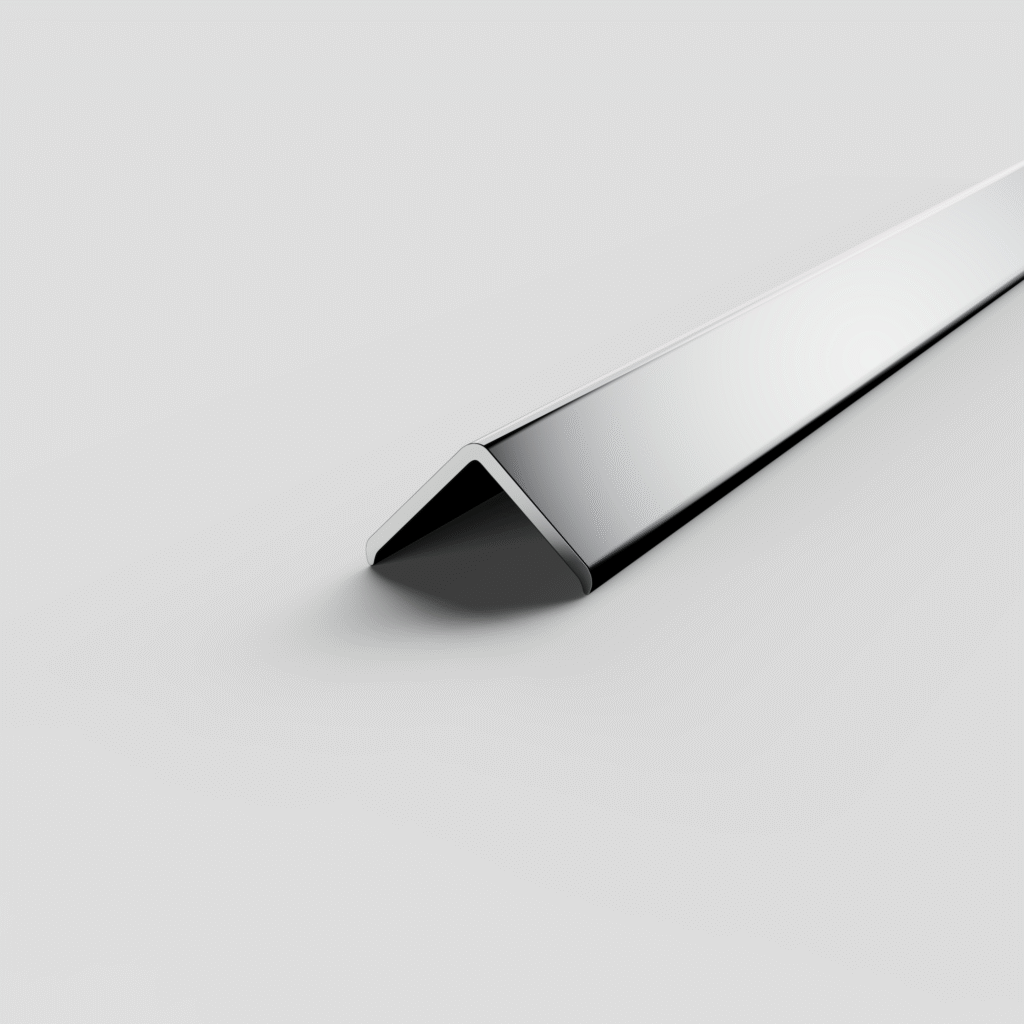

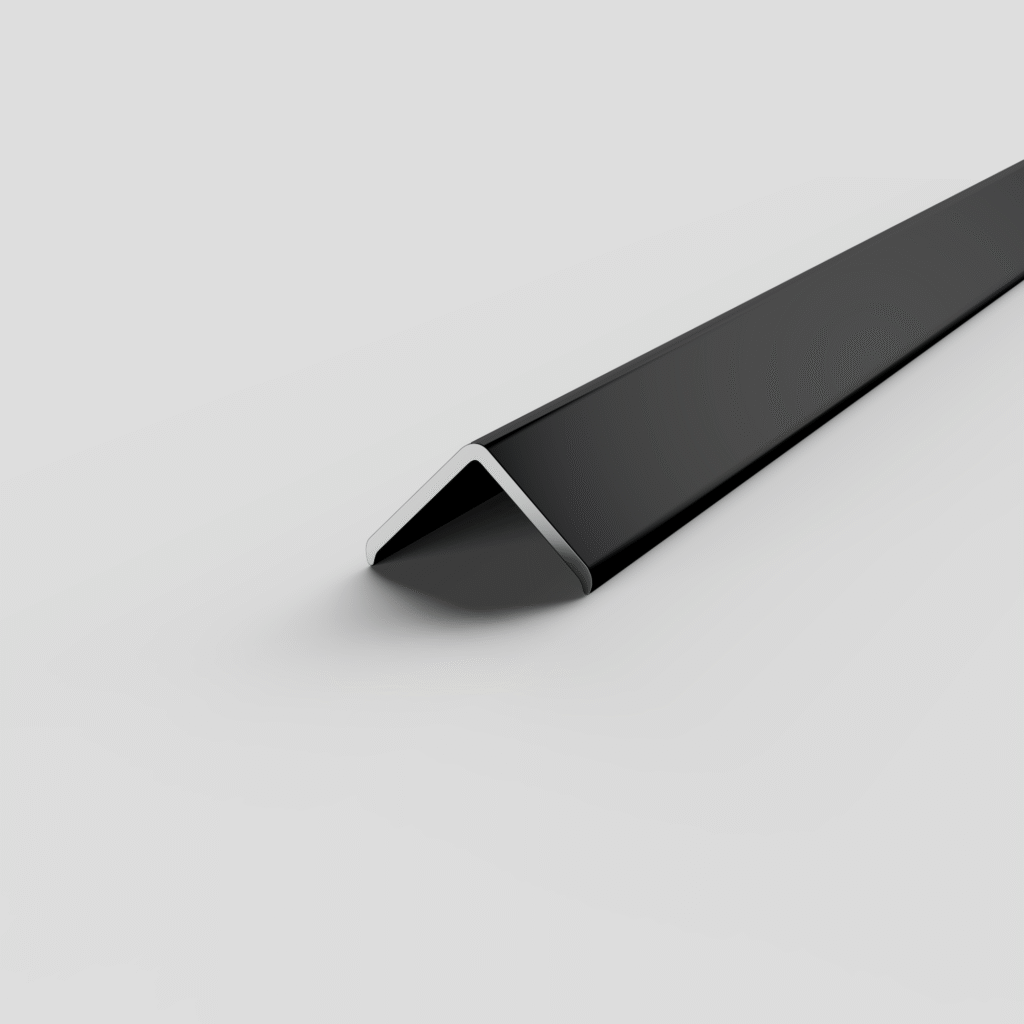

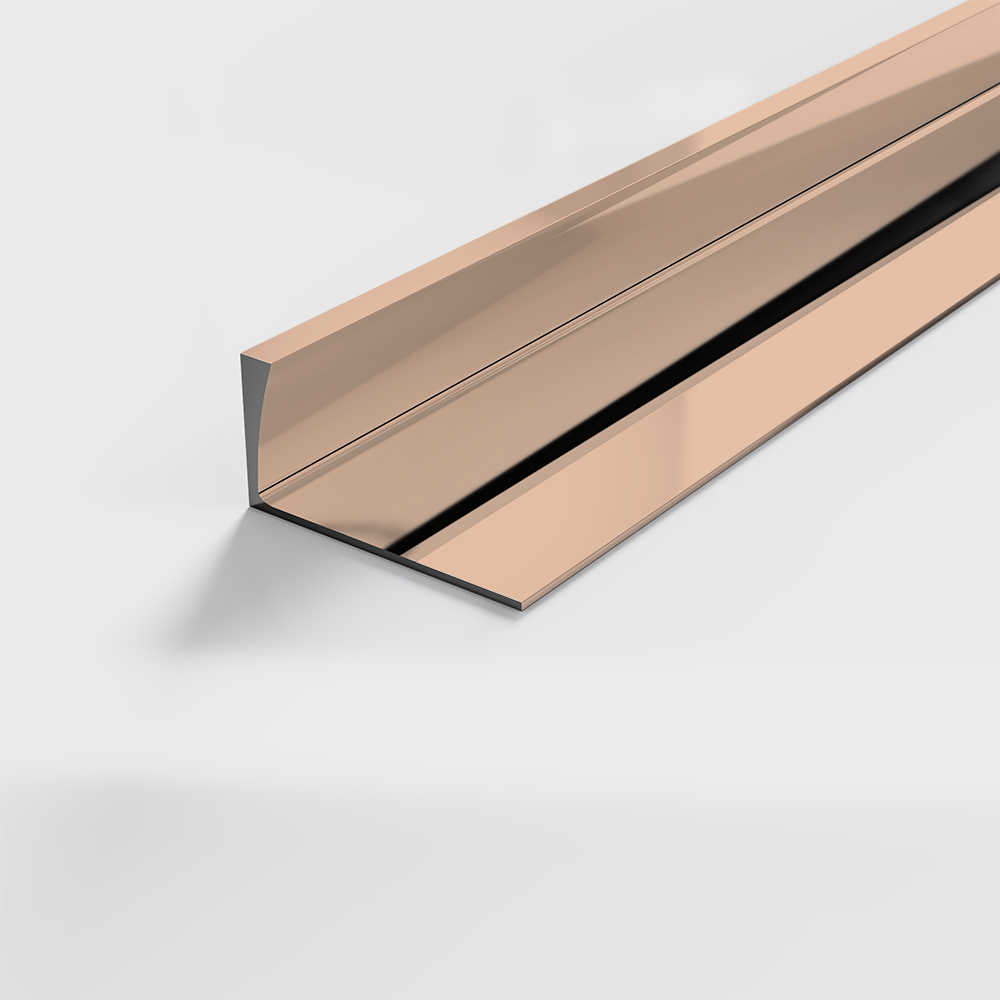

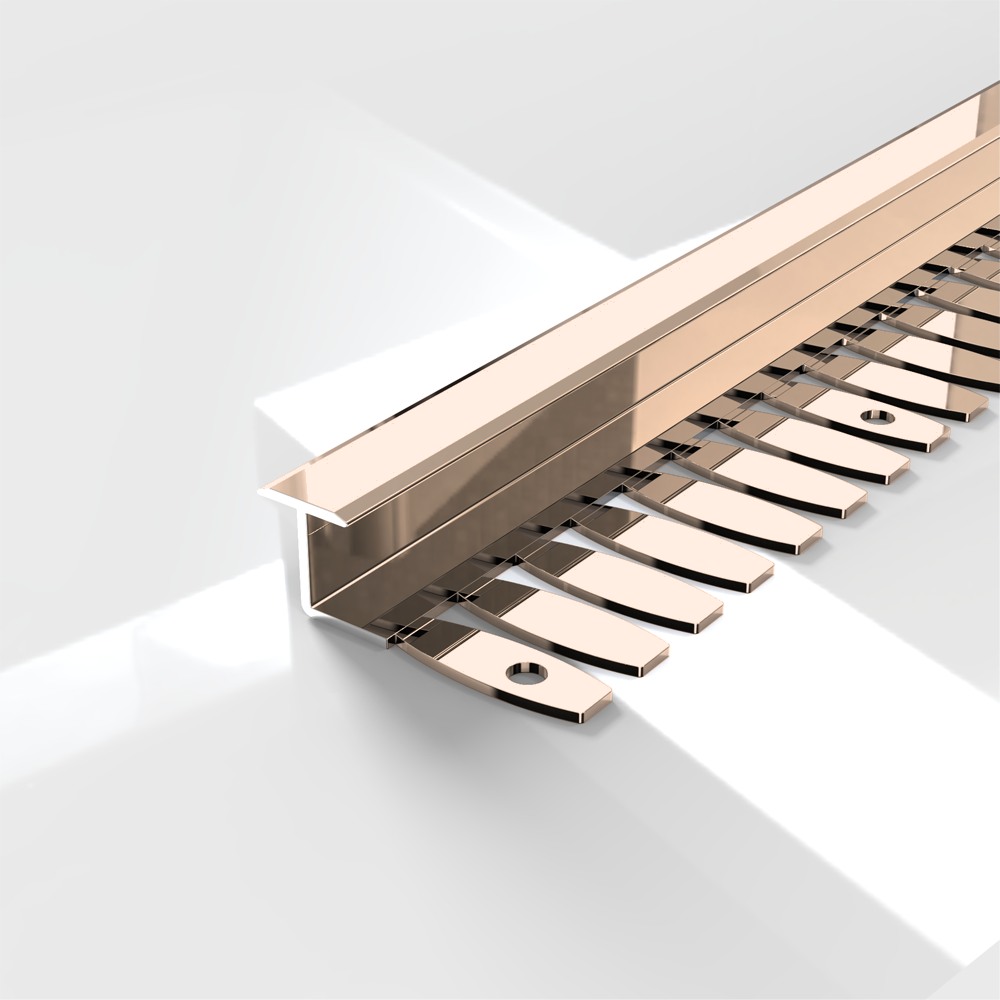

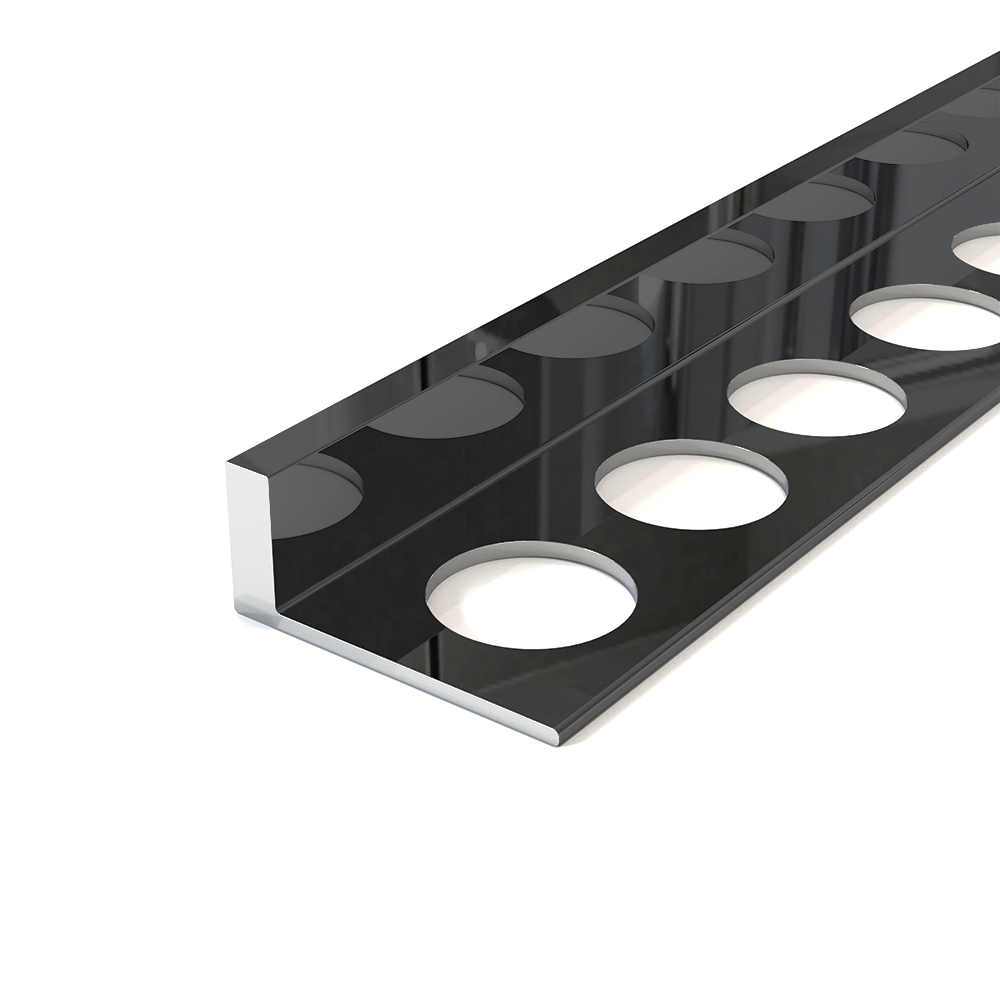

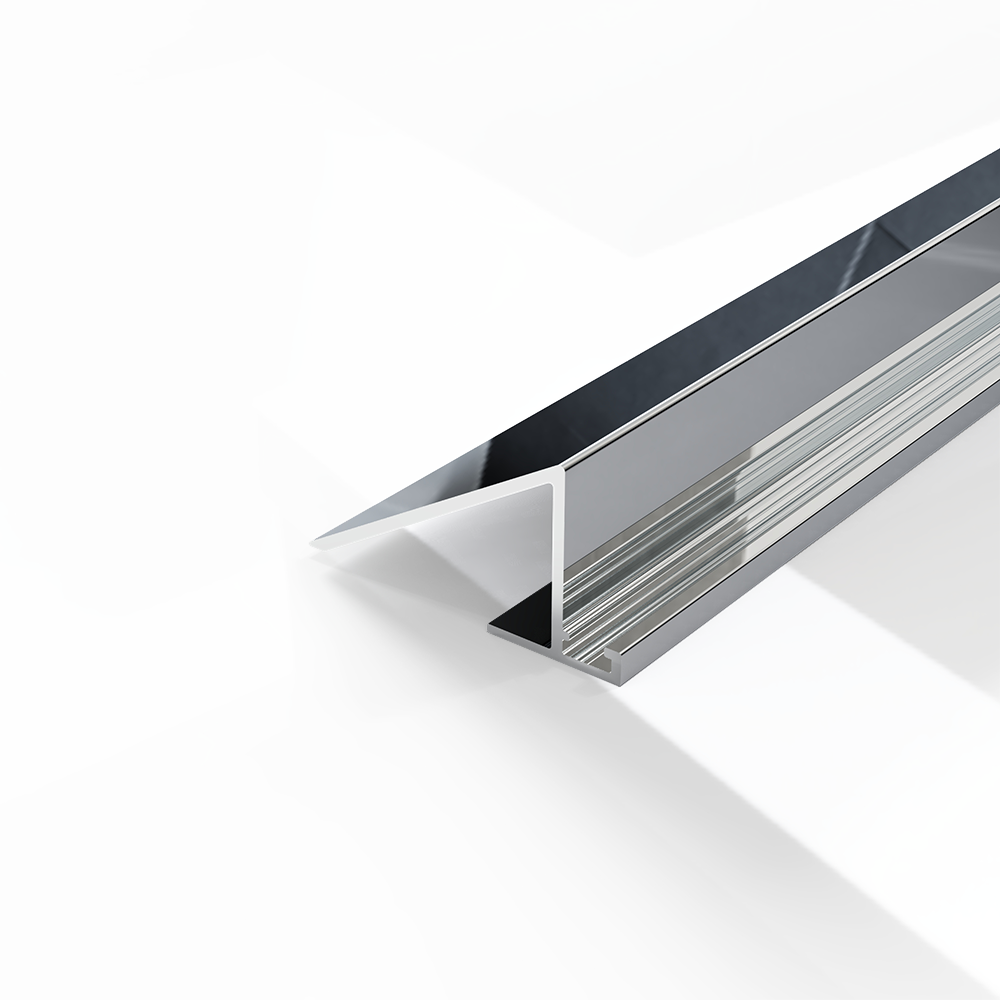

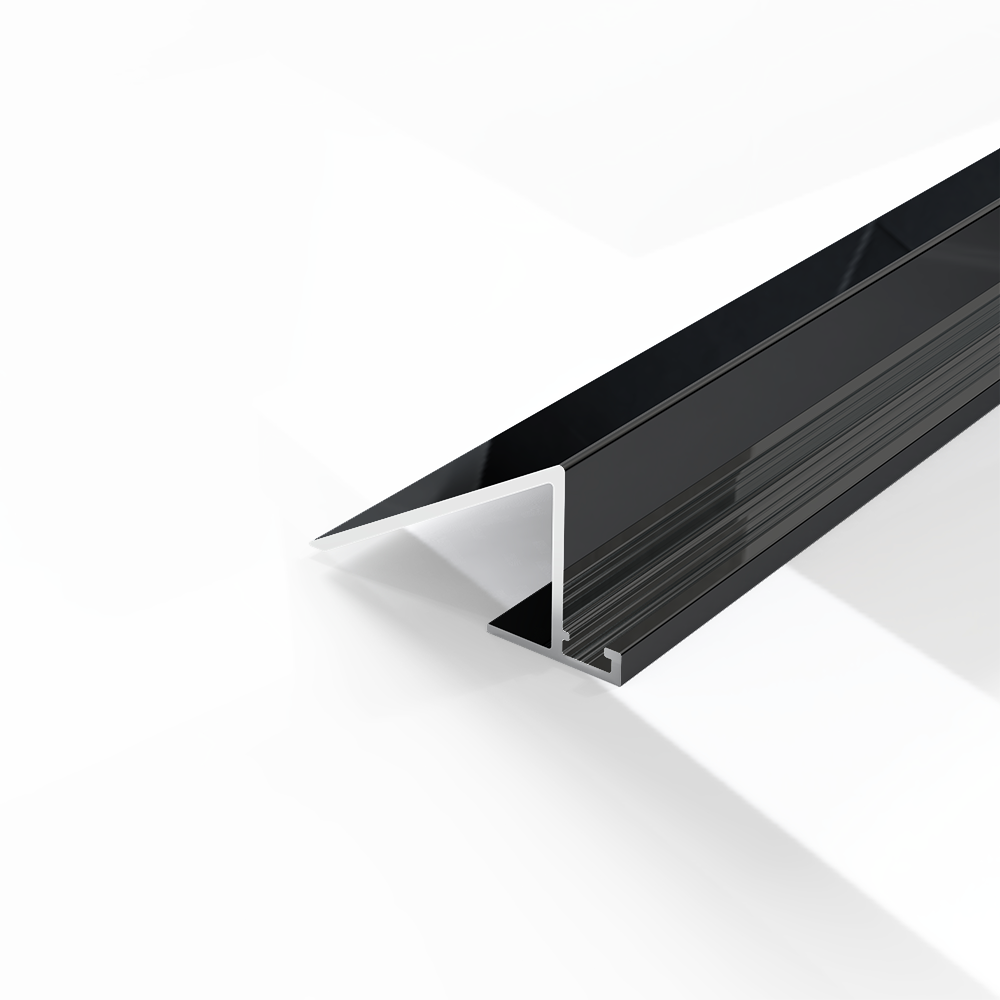

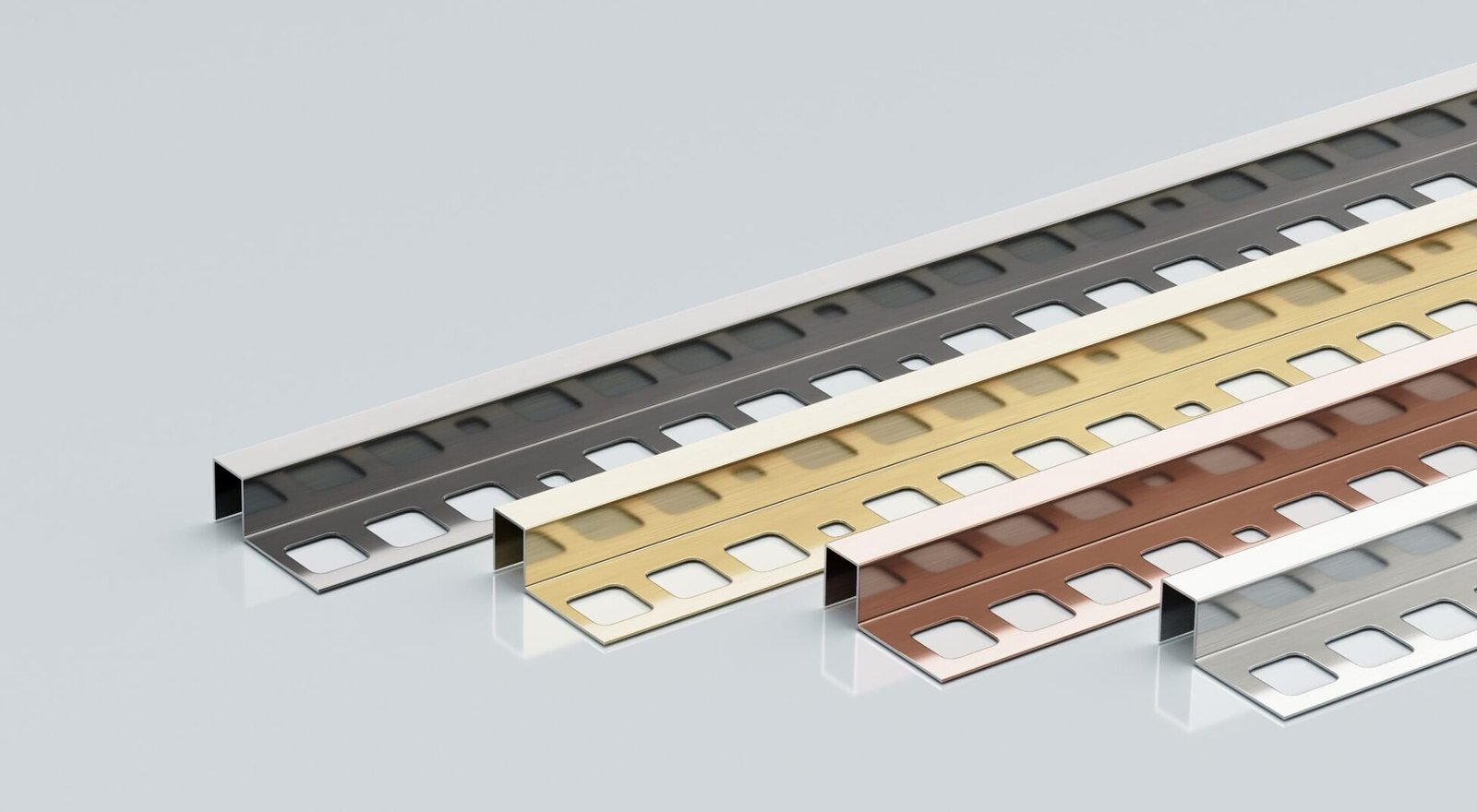

- Dyeing (Optional): The porous layer undergoes color application through immersion in dye baths to achieve different finishes. The addition of organic dyes and electrolytic coloring techniques produces black, gold and bronze shades for the trim to match tile aesthetics.

- Sealing: The pores receive closure through boiling water treatment or nickel acetate solution application. The sealing process enhances color retention while delivering superior stain and corrosion protection.

How Anodizing Elevates Aluminum Tile Trim Performance

Anodized aluminum tile trim proves useful in both residential and business environments:

- Enhanced Surface Hardness to Avoid Scratches: The oxide layer functions as a protective barrier which makes the trim more resistant to tool abrasions and daily wear thus extending its pristine condition.

- Forming a Protective Layer to Resist Moisture Corrosion: The barrier function protects it from rust and degradation thus making it suitable for bathrooms and kitchens in wet areas.

- Providing Rich Color Choices to Match Various Decoration Styles: The variety of finish options including matte and glossy allows for seamless integration with contemporary and rustic as well as minimalist design schemes.

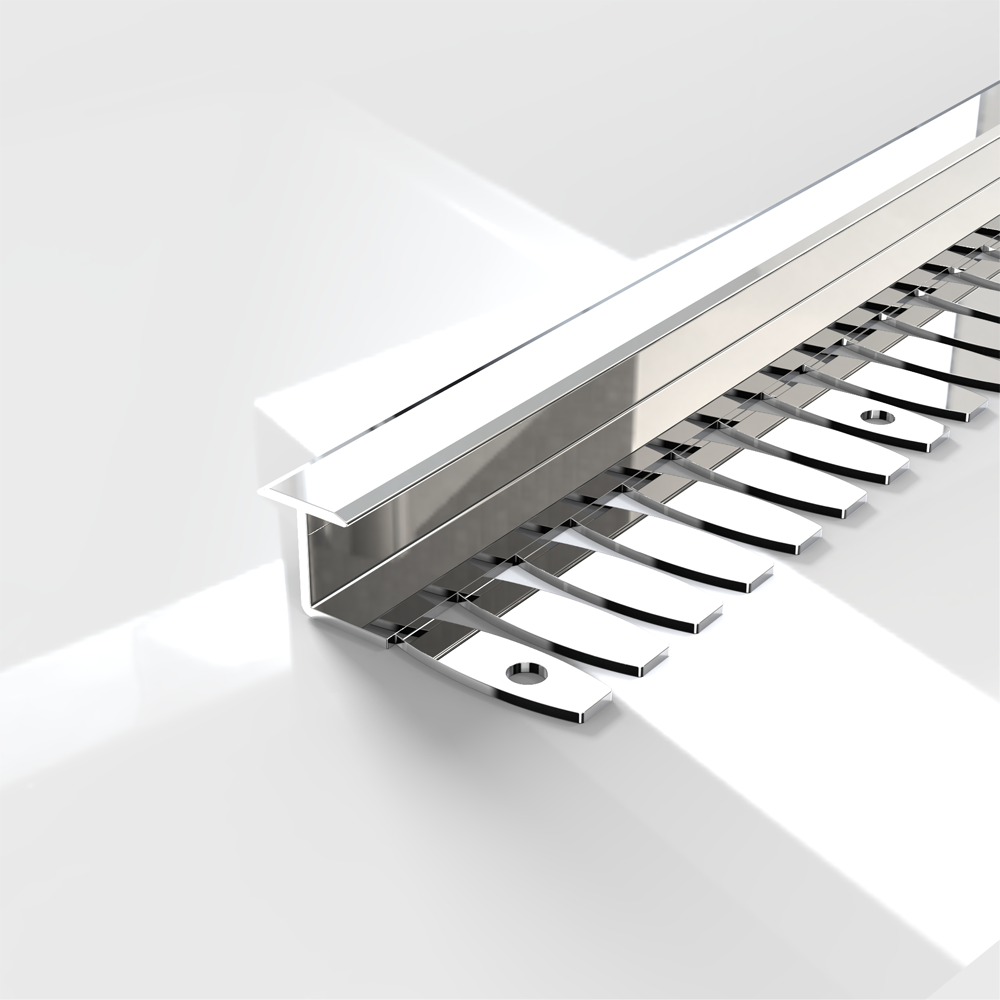

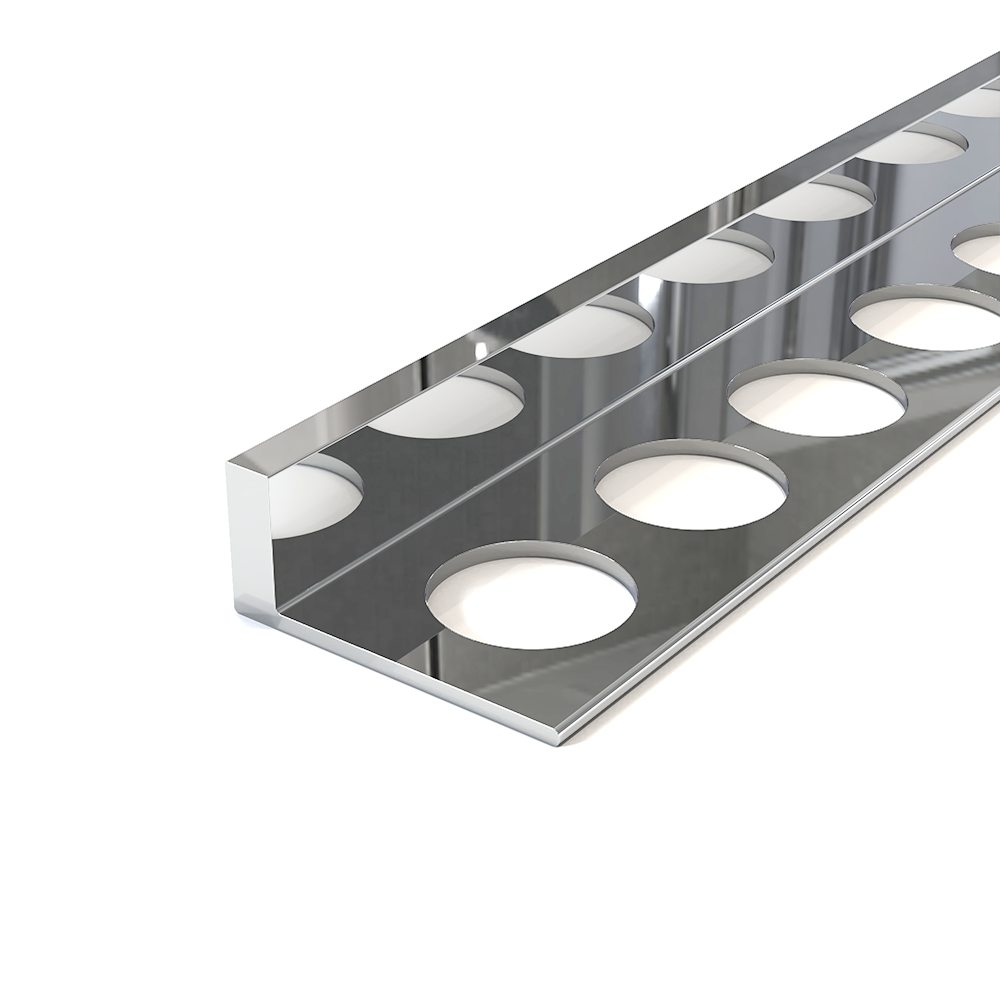

Discover premium anodizing aluminum tile trim from Senmry and click below to explore our products:

Common Questions Answered (FAQ)

- The anodizing treatment will it remain intact?

The oxide layer integrates permanently with the aluminum material so it stays intact under regular use conditions unlike paints.

- What locations make Anodized Aluminum Tile Trim suitable?

Anodized aluminum tile trim works well for all indoor spaces including bathroom, kitchen, floor and wall applications. Outdoor UV exposure along with harsh chemicals should be avoided because it works well in sheltered patio settings.

Anodized aluminum tile trim represents a wise investment choice because it delivers both durability and attractive aesthetic results. The correct installation method helps extend product life while minimizing upkeep needs.

Our Products

Latest Articles

Get A Free Sample

Try out the products you are interested in and get free samples. See the quality for yourself and let’s start working together right away.

Get In Touch Today

After you fill out the form, We will contact you within 24 hours.

The first objective will be to understand your needs, then develop a business plan together and provide you with the best pricing!

Address

Workshop No. 3 (Self - designated), Sizhong Industrial Zone, Dazhen Community, Dali Town, Nanhai District, Foshan City

Tel

+86 13392243769

+86 13392243769

senmry@vip.163.com