Stainless Steel or Aluminum Alloy Performance Guide

Two metals dominate the decoration materials market: stainless steel and aluminum alloy. These two materials serve extensive applications because they possess special qualities that make them perfect for kitchen backsplashes alongside furniture and architectural features. The decision process for selecting material for your project depends on your understanding of their distinguishing characteristics. The article provides an extensive comparison of stainless steel and aluminum alloy properties to assist readers in making their selection.

Basic Properties

Composition and Structure

Stainless steel obtains its corrosion resistance through its iron base which contains at least 10.5% chromium. Additional elements such as nickel titanium and molybdenum together with titanium help improve specific characteristics of the material. The primary material in aluminum alloy is aluminum yet it contains copper silicon magnesium and zinc to boost its strength and durability.

Appearance and Texture

The steel presents a traditional metallic silver-white color with a glossy finish that produces a cold hard surface suitable for modern and industrial design applications. The silver-white or gray color of this alloy can receive various anodic treatments to produce different colors and finishes that result in a lightweight appearance suitable for various design applications.

Strength and Hardness

Stainless steel demonstrates exceptional strength and hardness which makes it suitable for applications needing durability along with resistance to wear. The material demonstrates excellent performance in compressive and tensile strength applications for structural components. The weight of aluminum alloy remains lower than stainless steel since it has a higher strength-to-weight ratio despite lacking hardness. Heat treatment combined with alloying techniques enables significant strength enhancement which positions this material as a strong candidate for particular applications.

Weight

Weight serves as the major distinction between stainless steel and aluminum alloy. The lightweight characteristics of aluminum alloy become essential for weight reduction requirements in applications such as aerospace-inspired designs and transportation systems. The heavier density of this metal provides stability yet makes it impractical for projects needing weight reduction.

Corrosion Resistance

The resistance to corrosion stands as an essential requirement for decoration materials since they face moisture and chemical and salt exposure in various environments. The corrosion protection of stainless steel material through its 304 and 316 grades occurs through a passive chromium oxide layer which shields the material against acids alkalis and salt fog thus making it suitable for marine and outdoor applications. The protective oxide layer formed by aluminum alloy does not provide the same level of protection as stainless steel because it tends to experience pitting and electrochemical corrosion in severe conditions. The anodizing process enhances its resistance but the steel exhibits better performance in severe conditions.

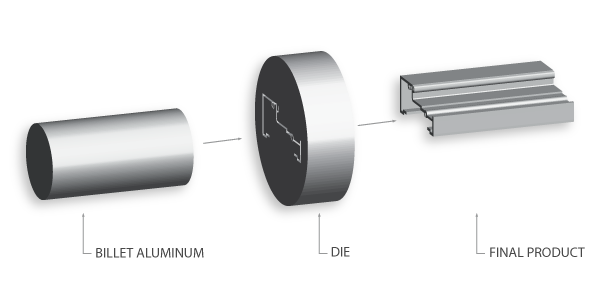

Workability and Formability

The fabrication process benefits more from aluminum alloy. The material offers simple casting and extrusion and stamping and cutting operations which enables the creation of complex decorative elements. The forming processes of stainless steel work-harden to such an extent that it becomes more difficult to work with compared to aluminum alloy. The deep drawing process enables the creation of seamless components which provide distinctive fabrication methods.

Cost Considerations

Material selection costs play a vital role in the decision-making process. The raw material and processing expenses for aluminum alloy prove lower than stainless steel because stainless steel demands higher initial costs from raw materials and specific cutting requirements. The steel provides longer-term value because of its durable properties despite its higher initial cost.

Stainless Steel vs Aluminum Alloy Comparison

|

Property |

Stainless Steel |

Aluminum Alloy |

|---|---|---|

|

Composition |

Iron, chromium (10.5%+), nickel, etc. |

Aluminum, copper, silicon, magnesium, zinc |

|

Appearance |

Silver-white, high gloss, cold texture |

Silver-white/gray, anodizable, modern texture |

|

Strength & Hardness |

High strength, hard, durable |

High strength-to-weight ratio, less hard |

|

Weight |

Dense, heavier (3x aluminum) |

Lightweight, ~1/3 density of steel |

|

Corrosion Resistance |

Excellent, especially in marine environments |

Good, but prone to pitting; anodizing helps |

|

Workability |

Workable, but prone to work-hardening |

Easy to cast, extrude, stamp, cut |

|

Cost |

Higher raw material and processing costs |

Lower raw material and processing costs |

Key Decision Guide: How to Choose?

The selection between stainless steel and aluminum alloy depends on your project needs. The following points will guide your selection process:

- Primary Requirements: Determine which factor matters most in your project such as lightweight construction or resistance to corrosion or strength or affordability. Weight-sensitive applications need the alloy selection while stainless steel works best for projects requiring durability.

- Environmental Conditions: Assess how the materials will react to corrosive substances and thermal changes and mechanical The marine or chemical-heavy environment demands stainless steel as the preferred material.

- Budget and Fabrication: Assess the total cost, including material and processing, as well as the ease of fabrication. For budget-friendly or complex projects the aluminum alloy could be used due to its cost efficiency.

Each material has its own set of benefits and there is no single material that stands out as the best choice. Stainless steel is recommended for all applications requiring durability and resistance to corrosion such as outdoor fixtures and structural components. For modern furniture and decorative panels aluminum alloy proves to be the best option because it is versatile and lightweight.

Conclusion

Stainless steel and aluminum alloy differ in their decoration-related benefits. Steel has superior corrosion resistance and strength which makes it suitable for harsh environments and structural applications. Modern designs together with weight-sensitive projects require the alloy because of its lightweight nature and versatile finishing options. Understanding material properties will help you select the best material for your project because it will surpass your performance and aesthetic expectations.

Our Products

Latest Articles

Get A Free Sample

Try out the products you are interested in and get free samples. See the quality for yourself and let’s start working together right away.

Get In Touch Today

After you fill out the form, We will contact you within 24 hours.

The first objective will be to understand your needs, then develop a business plan together and provide you with the best pricing!

Address

Workshop No. 3 (Self - designated), Sizhong Industrial Zone, Dazhen Community, Dali Town, Nanhai District, Foshan City

Tel

+86 13392243769

+86 13392243769

senmry@vip.163.com