Surface Treatments for Tile Edge Trim

The tiling process depends on tile edge trim as an essential element because it protects the edges while adding decorative value. The complete potential of tile edge trim becomes accessible through sophisticated surface treatment methods. These methods enhance both the visual attractiveness while significantly boosting durability which enables tile edge trim to work in different settings from bathrooms and kitchens through to commercial buildings. The article investigates surface treatment methods for tile edge trim together with their advantages while providing guidance on selecting appropriate treatments for your project.

Why Surface Treatment Matters for Tile Edge Trim

The process of surface treatment creates the essential foundation which enables tile edge trim to both perform well and appear beautiful. It serves multiple purposes:

- The surface treatment provides different color options and finish choices which enable the trim to match or enhance various design aesthetics from contemporary to vintage.

- The protective coatings make the trim resistant to corrosion as well as environmental harm and physical deterioration which protects it in busy or damp conditions.

- The correct treatment of tile edge trim makes it resistant to normal wear and tear so it can sustain its visual quality throughout numerous years without requiring

Investment in premium surface treatments enables better functionality and enhanced beauty for your tiling projects.

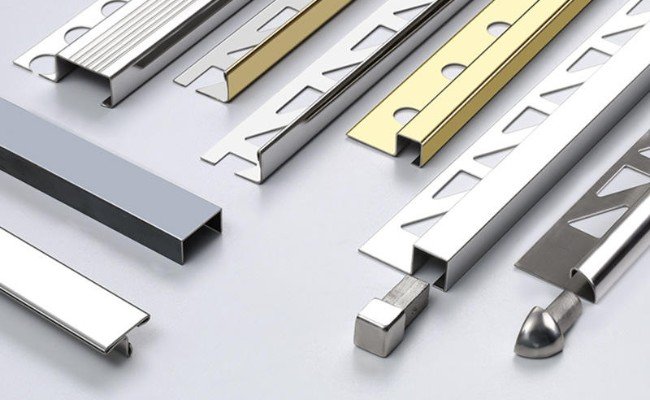

Top Surface Treatment Options for Tile Edge Trim

Advanced surface treatment technologies exist to enhance tile edge trim functionality and quality. Different surface treatment approaches bring unique performance benefits which make them appropriate for various use cases.

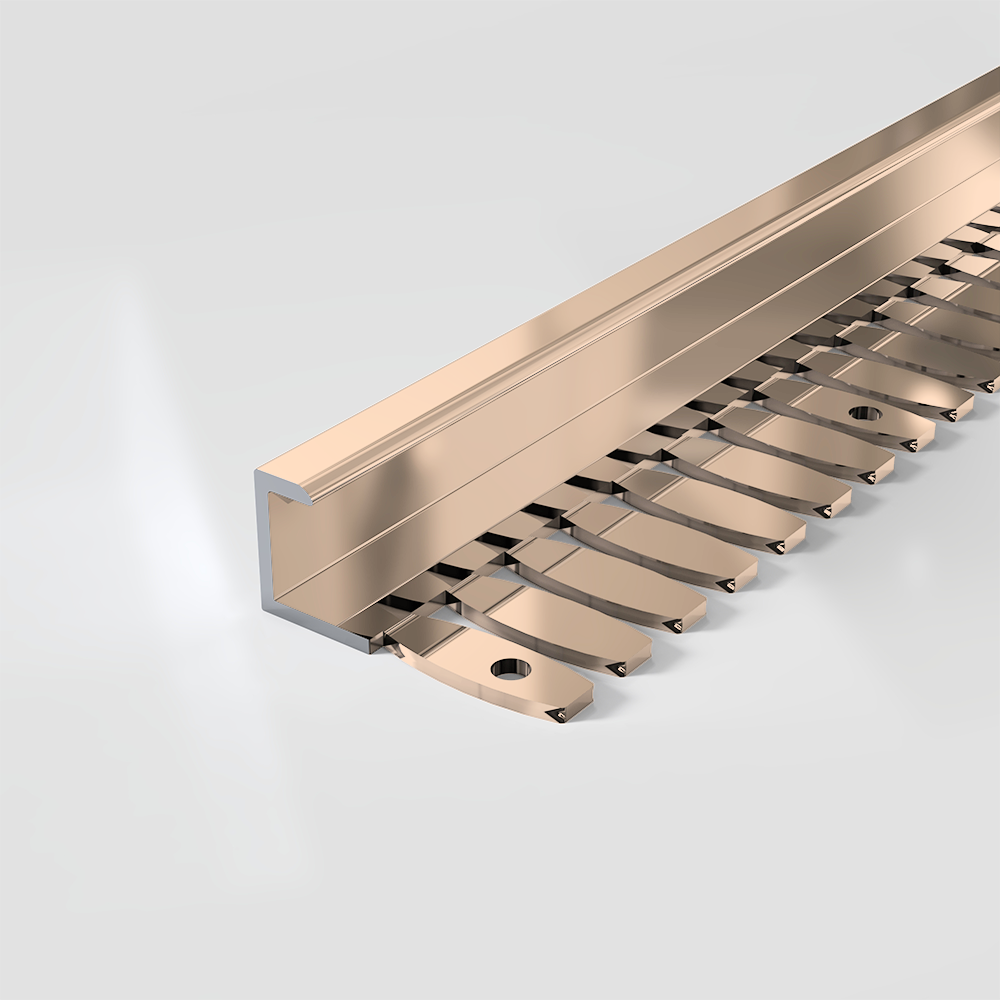

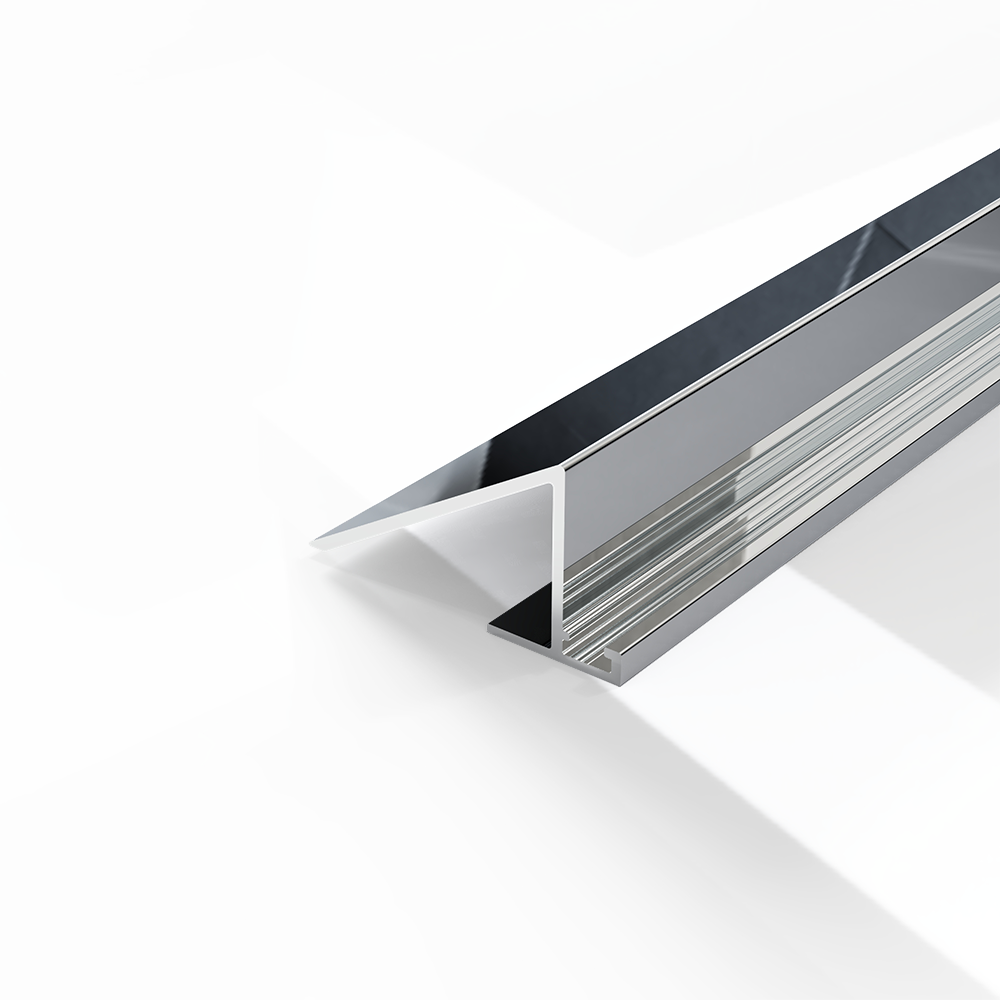

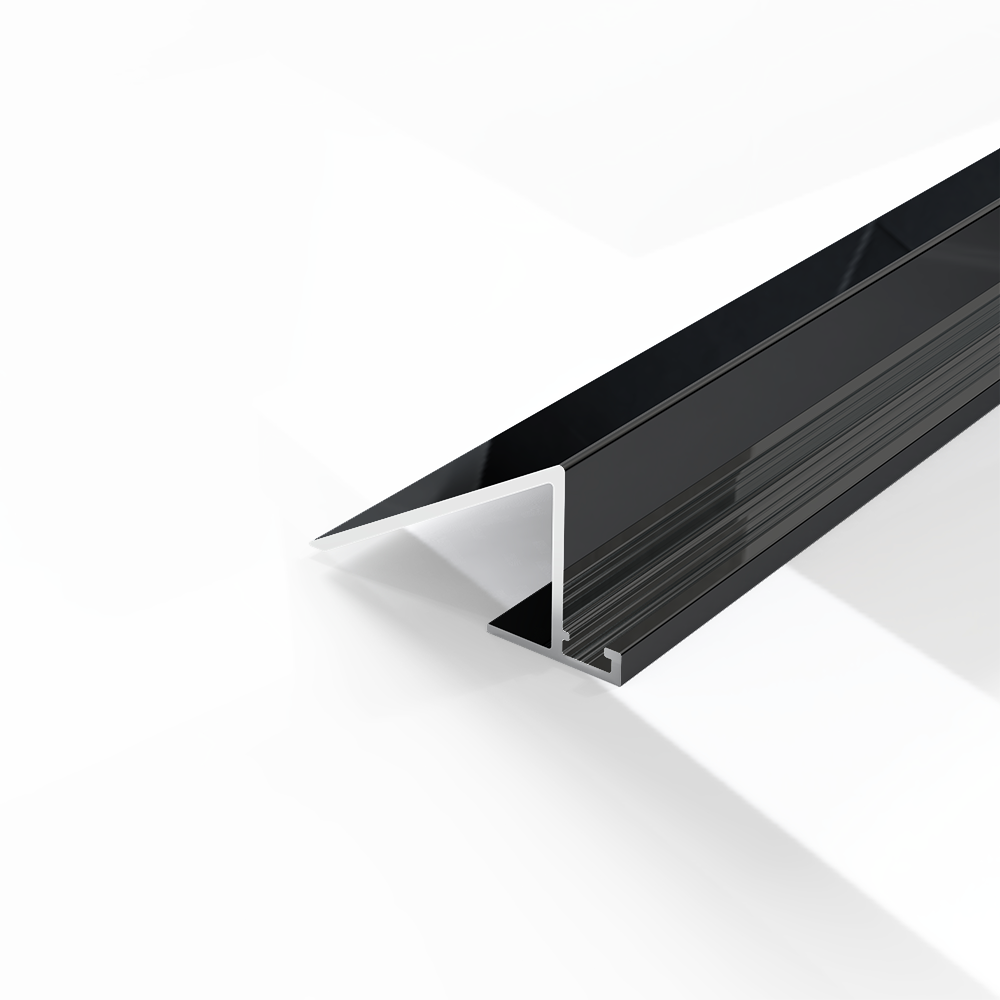

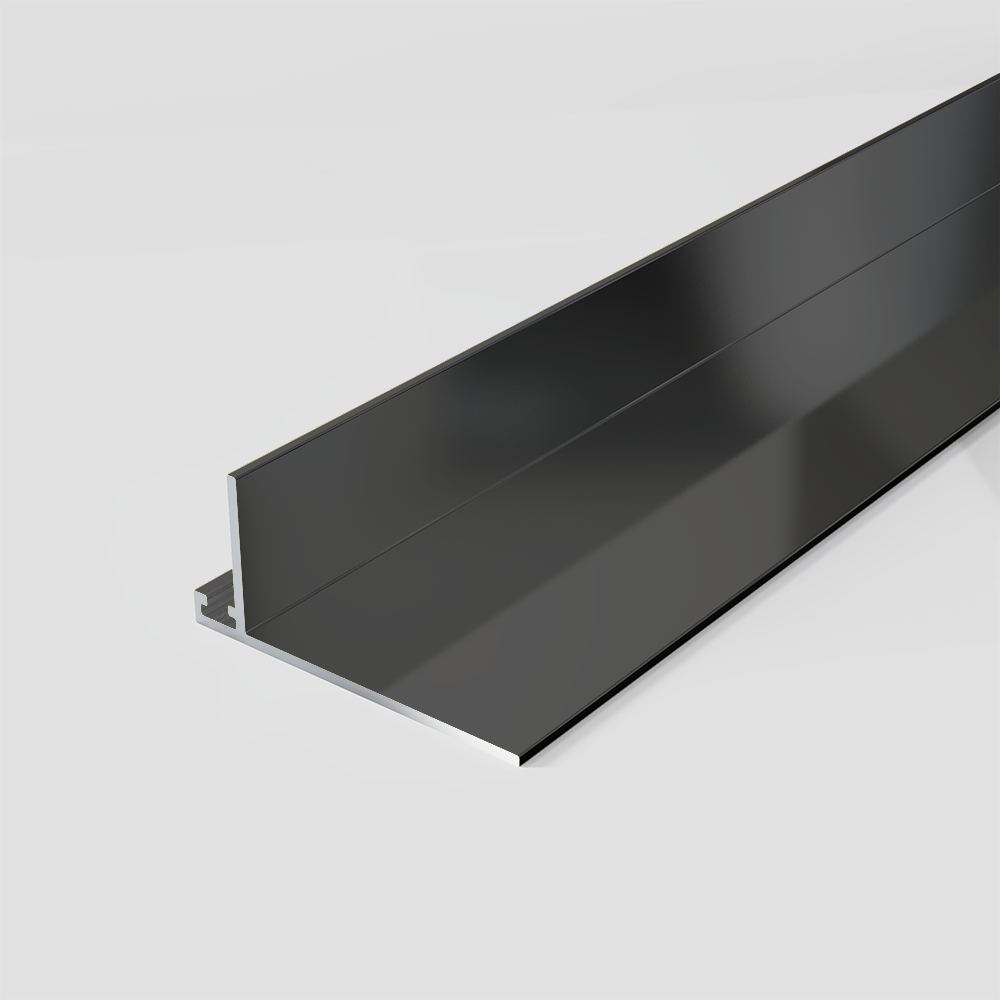

1. Anodizing: The Classic Choice for Aluminum Trim

- The anodizing process requires aluminum trim to enter an electrolyte bath where electric current forms protective oxide layers through immersion. Anodized trim has gained popularity because it both enhances appearance quality and improves functional

- Key Benefits:

(1)The anodized treatment protects the tile edge trim from corrosion in bathroom and kitchen environments.

(2)The hardened surface of this material offers both high wear resistance and physical protection for areas with heavy traffic.

(3)The range of available color options includes champagne gold, brushed silver, antique copper and black which enables design flexibility.

- The application field of anodized tile edge trim includes both interior and exterior spaces where durability along with visual appeal matter.

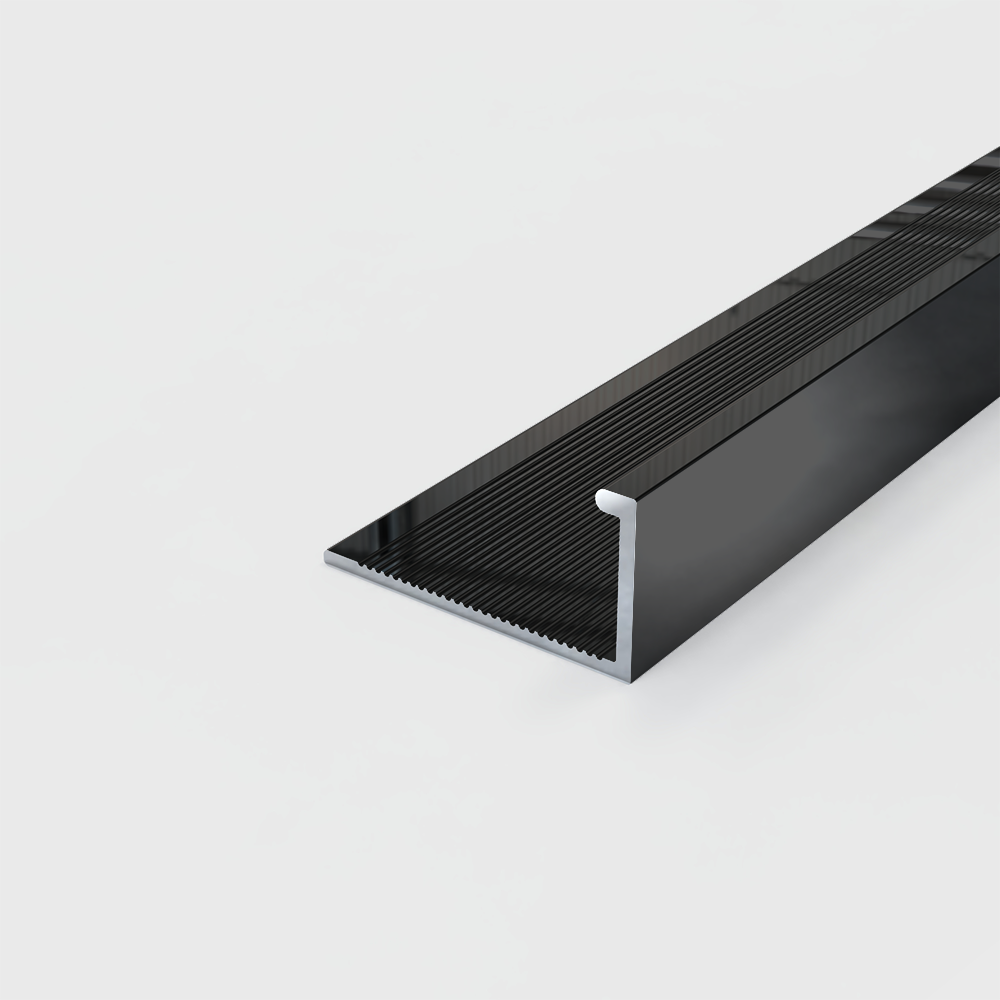

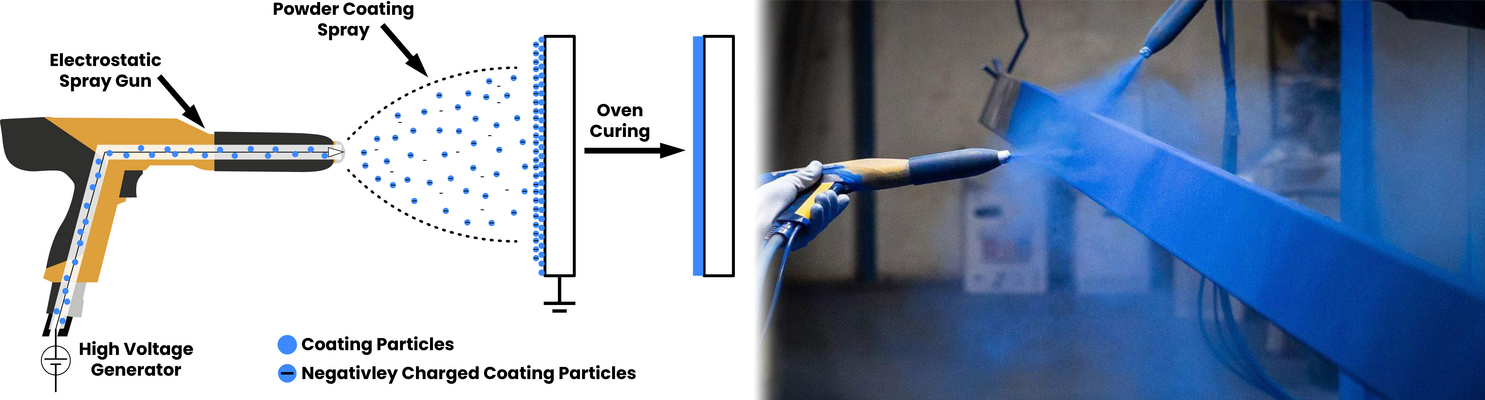

2. Powder Coating: Durable and Eco-Friendly

- The process starts with powder application through electrostatic means followed by baking to form a strong uniform film which bonds well with the trim material. The method achieves remarkable durability while providing environmentally friendly outcomes.

- Key Benefits:

(1)The powder coating provides UV and weather resistance that makes it suitable for outdoor applications.

(2)The durable coating layer guards the product from physical harm to deliver extended service life.

(3)The available finishes for this product include matte, gloss and metallic options that come in numerous color choices suitable for any design concept.

- The process produces minimal VOCs (volatile organic compounds) so it serves as an environmentally friendly option.

- This material works well for residential and commercial projects specifically in situations where harsh environmental conditions exist.

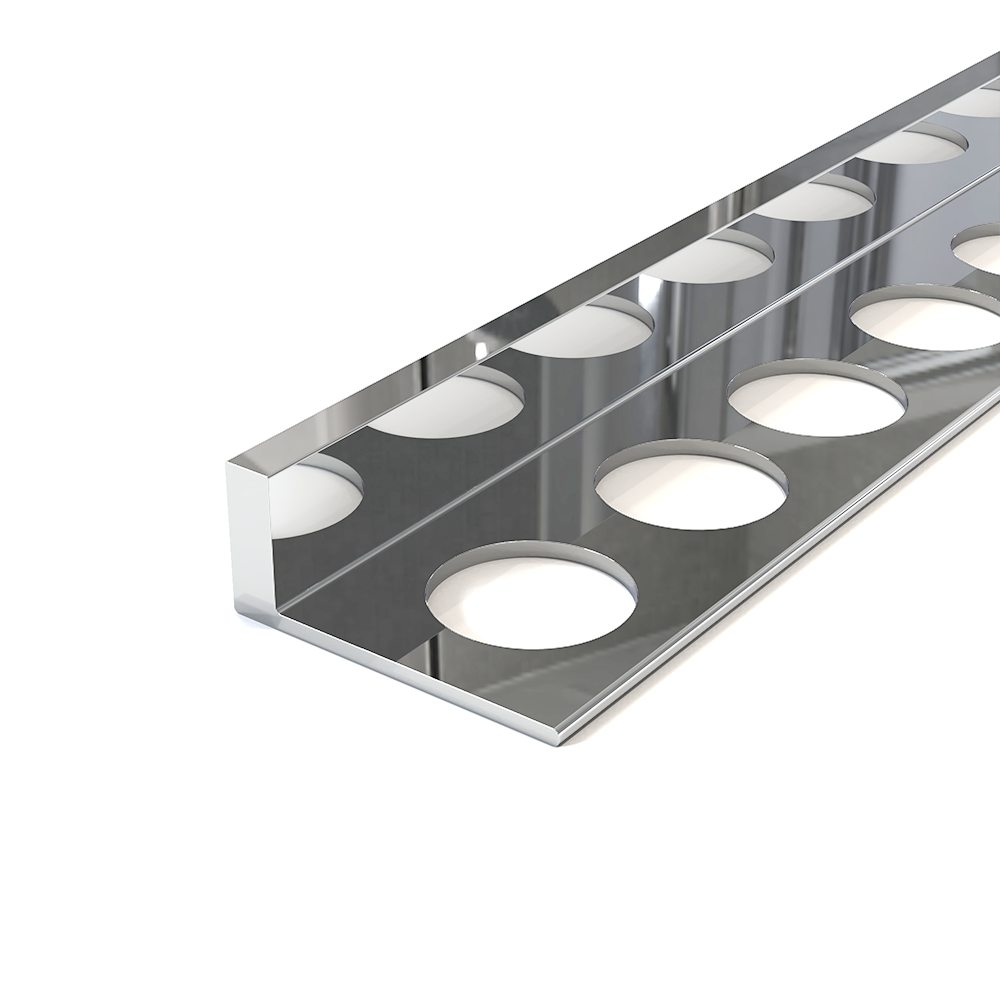

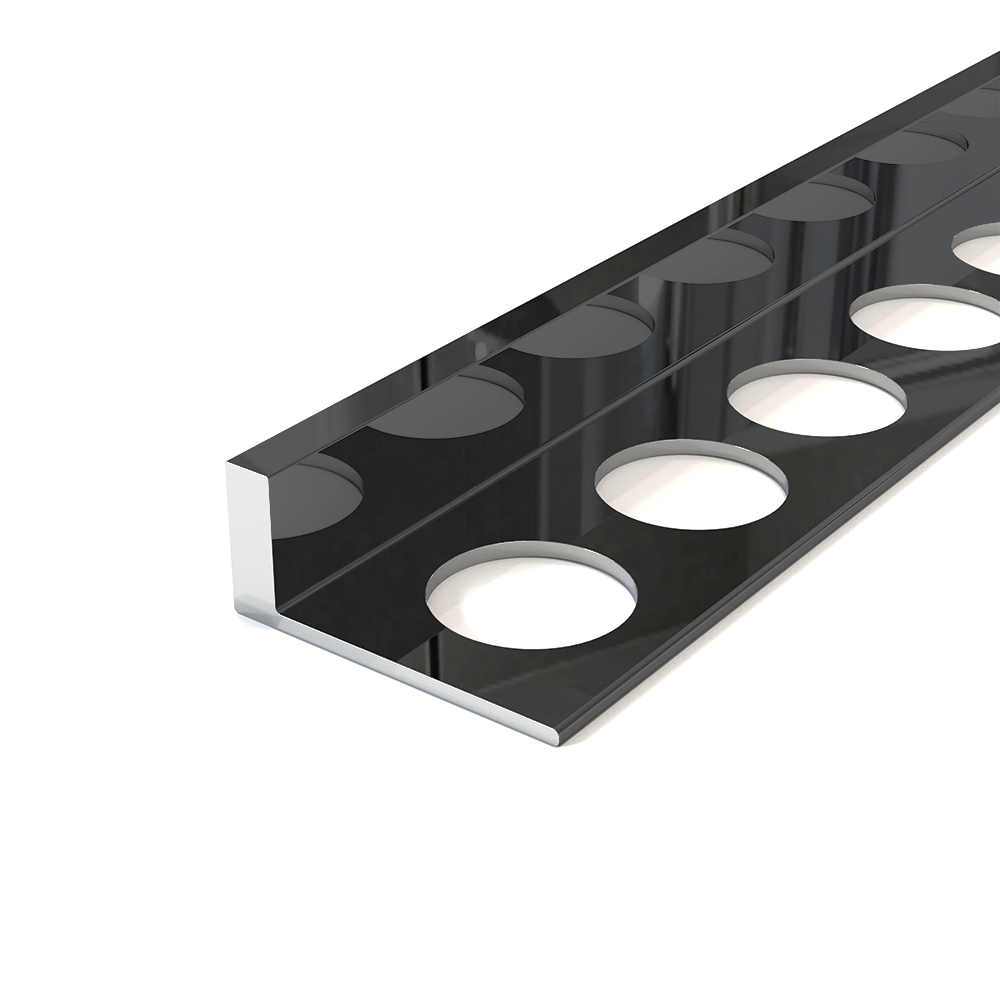

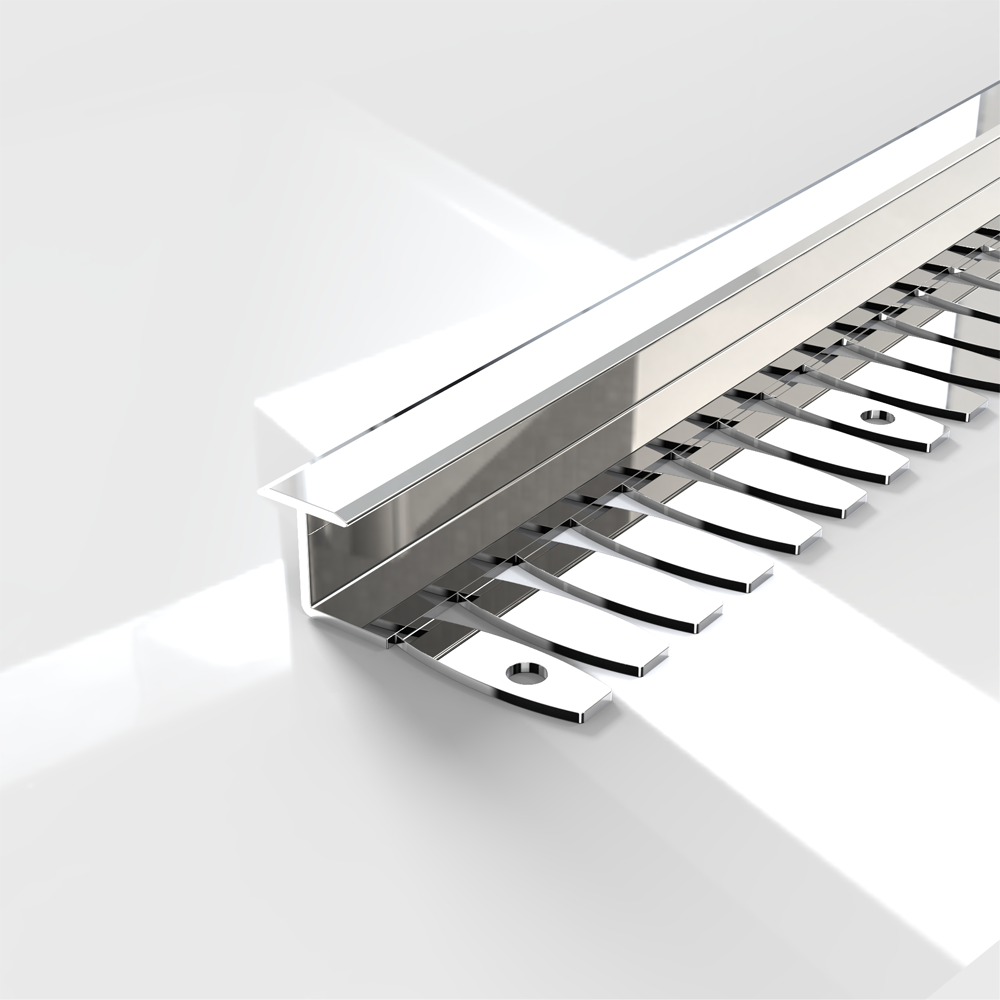

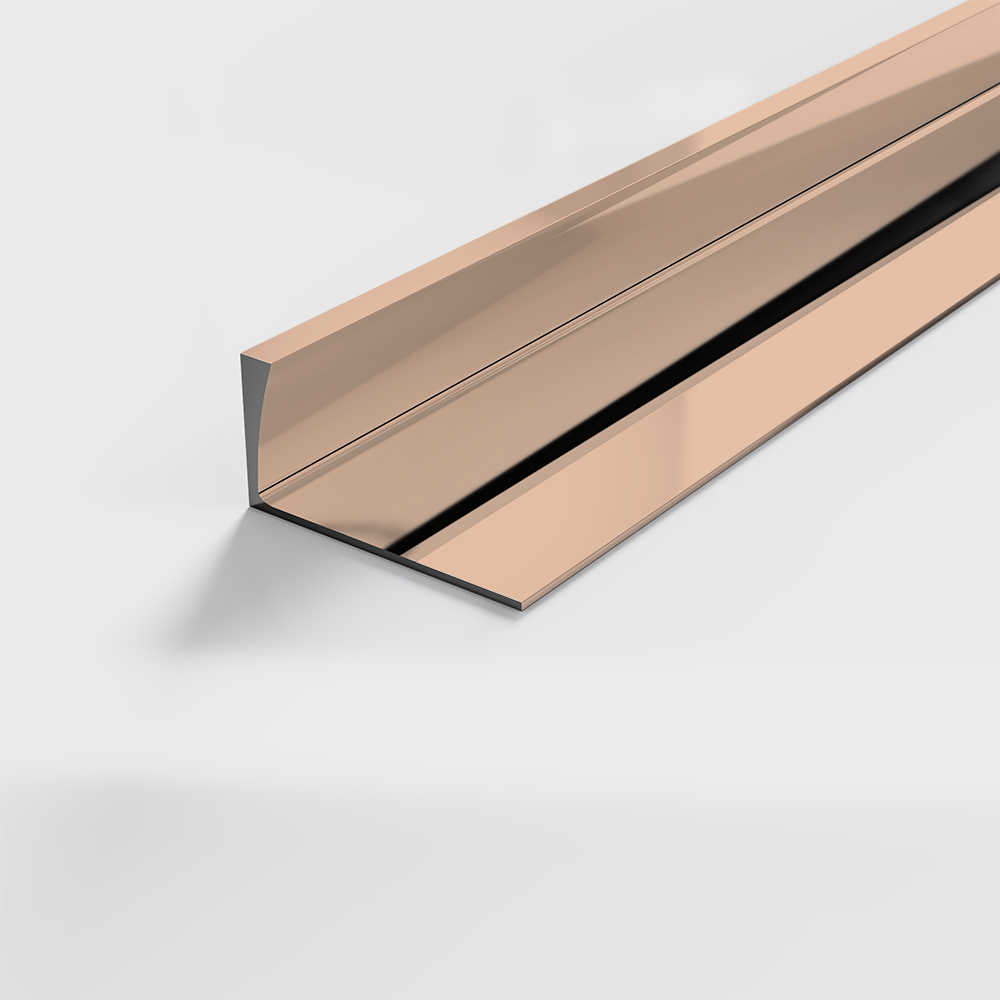

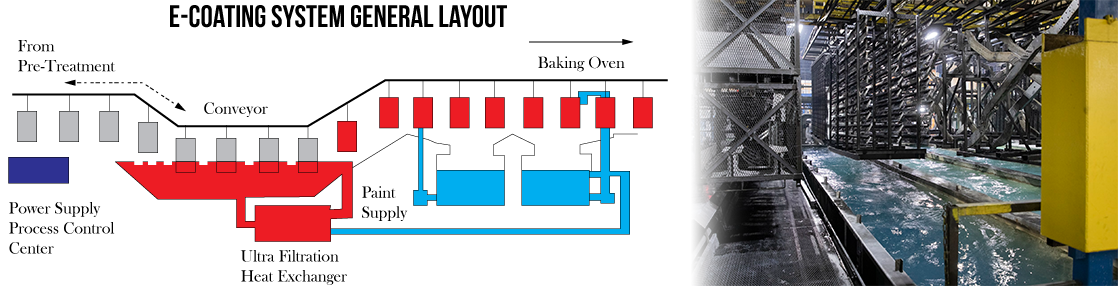

3. Electrophoretic Coating: Uniform and Protective

- The electric field creates uniform paint deposition throughout the trim while reaching challenging areas such as edges and corners when it is submerged in a paint bath.

- Key Benefits:

(1)The dense coating protects the material from moisture and chemicals thereby providing superior corrosion protection for wet environments.

(2)The finish appears perfectly uniform throughout the entire surface.

(3)The coating comes in high gloss or matte finishes and its colors will stay bright throughout its

(4)The strong chemical resistance along with excellent adhesion properties lead to longer product life.

- E-coating serves best in areas which need high corrosion resistance such as bathroom spaces and kitchen areas and outdoor applications.

Other Surface Treatment Options

Specialized treatments exist for particular project requirements beyond the standard methods.

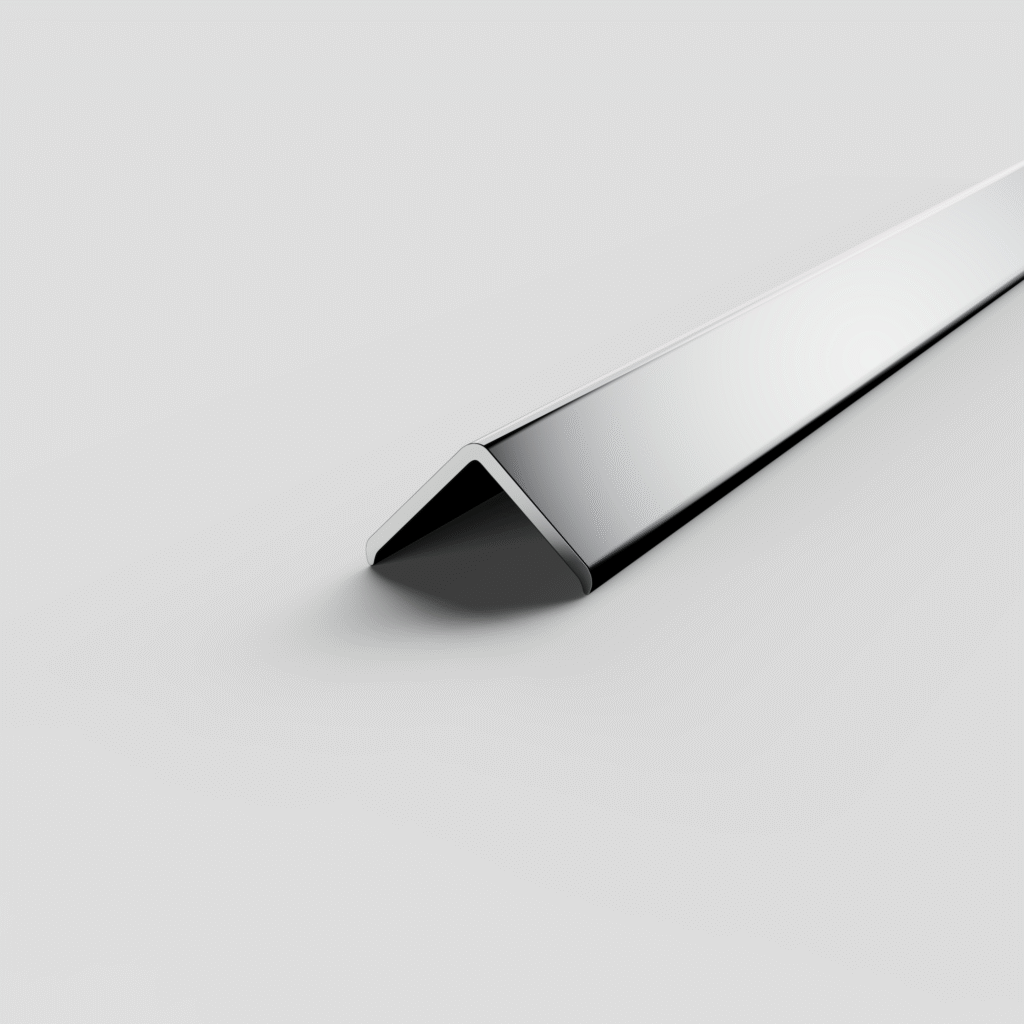

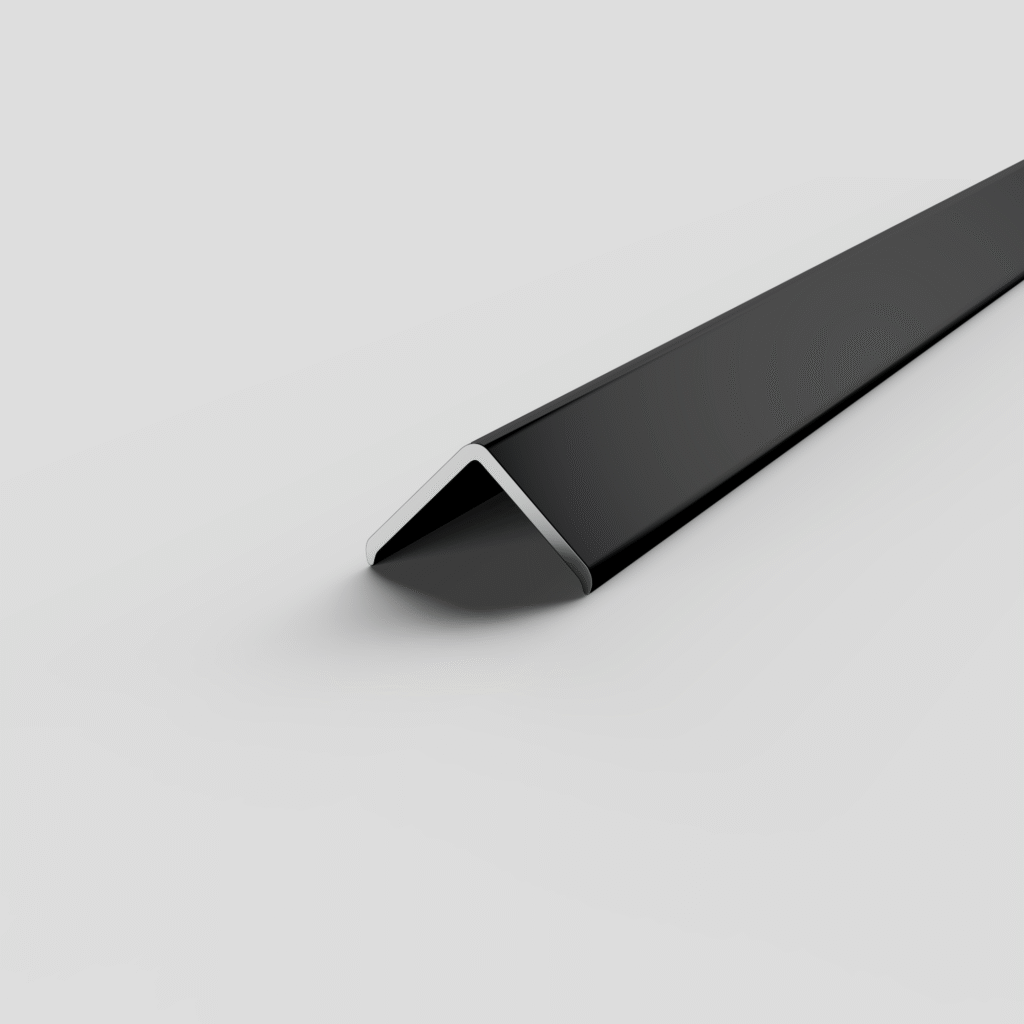

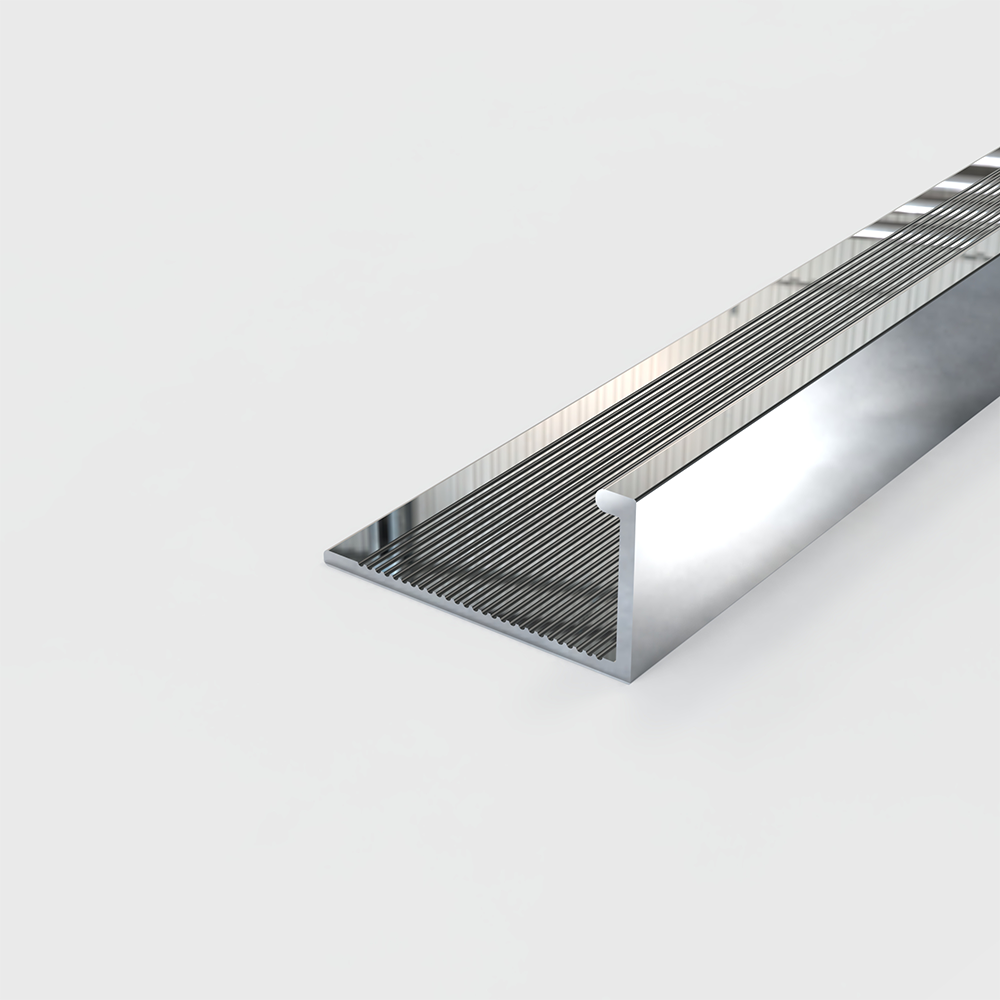

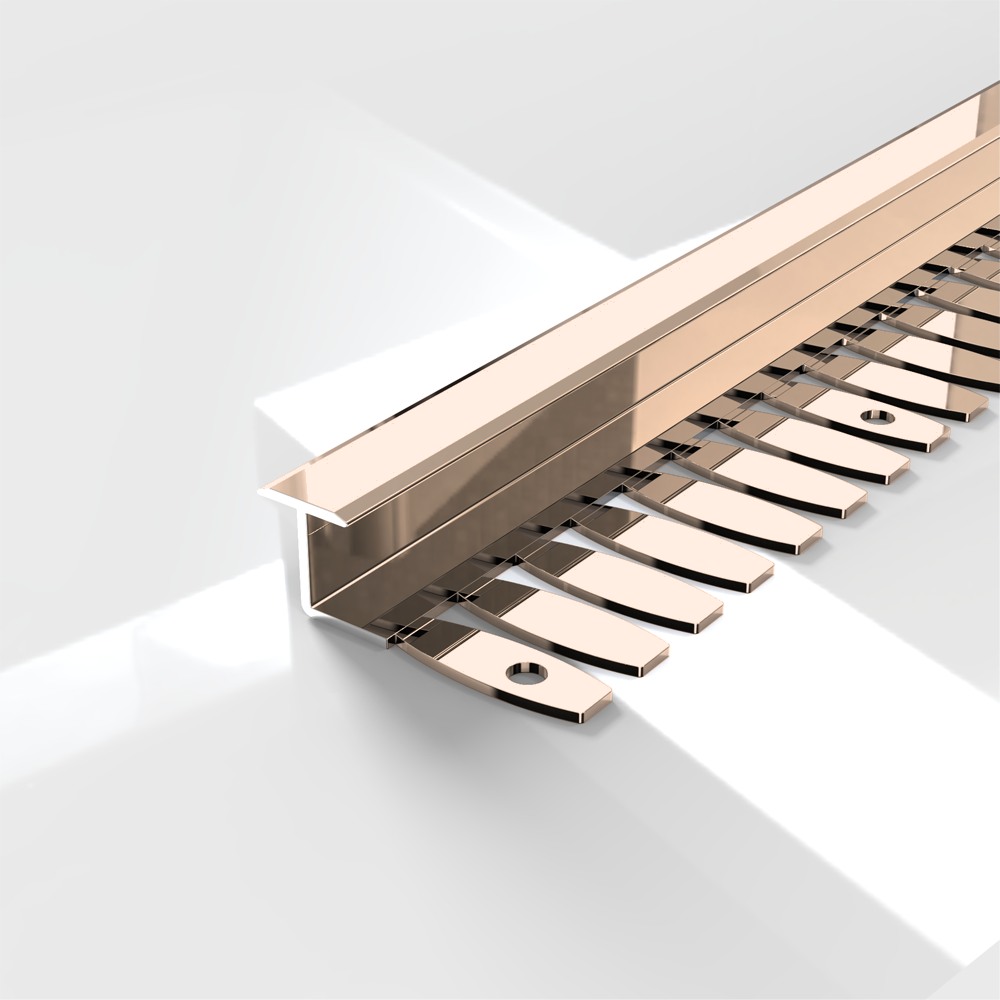

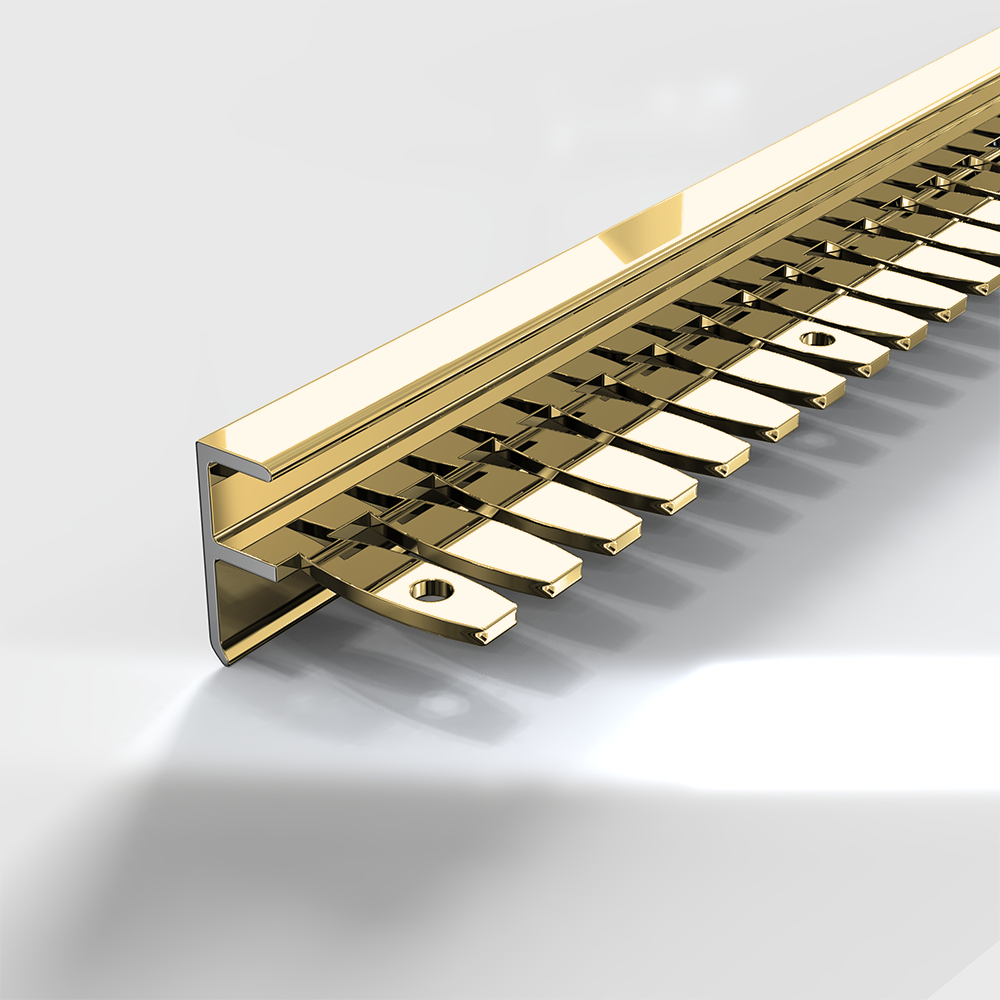

- The electroplating technique generates a thin chrome metal layer to produce luxurious high-shine finishes suitable for upscale designs.

- Brushing produces a surface design that creates linear patterns while adding modern sophistication to trim elements.

- The powder-coated surface receives the Wood Grain Transfer application which creates wood-like appearances suitable for natural and rustic

These extra surface treatment options enable designers to reach their distinct aesthetic or functional objectives.

Selecting the Right Surface Treatment for Your Tile Edge Trim

Several elements influence the selection of suitable surface treatment.

- The trim's intended location determines its surface treatment selection because it affects usage between bathrooms and kitchens and commercial settings and high-traffic zones. The excellent moisture-resistant properties of anodizing and e-coating make them suitable for wet areas but powder coating proves best for commercial environments.

- Select a finish and color that matches your design vision because you can choose between metallic and wood grain

- The surface treatment selection for high-traffic zones must include anodizing or powder coating because these materials offer superior durability and scratch resistance.

Conclusion

The process of producing high-quality tile edge trim heavily depends on surface treatment techniques. The three surface treatment options including anodizing and powder coating and electrophoretic coating provide separate advantages which will enhance your tiling project. The selection of surface treatment options depends on understanding them and matching them to your project environment and aesthetic requirements for creating long-lasting installations that enhance every space.

You can find detailed information about our surface-treated tile edge trim products through our product page or by contacting our customer service team for assistance with selecting the right tiling solution.

Our Products

Latest Articles

Get A Free Sample

Try out the products you are interested in and get free samples. See the quality for yourself and let’s start working together right away.

Get In Touch Today

After you fill out the form, We will contact you within 24 hours.

The first objective will be to understand your needs, then develop a business plan together and provide you with the best pricing!

Address

Workshop No. 3 (Self - designated), Sizhong Industrial Zone, Dazhen Community, Dali Town, Nanhai District, Foshan City

Tel

+86 13392243769

+86 13392243769

senmry@vip.163.com