Ultimate Wall Tile Trim Edging: Aluminum, PVC, or Steel?

In the world of home renovation and interior design, achieving a polished, professional finish often hinges on the subtle details—like the edges of your tiled surfaces. Wall tile trim edging plays a crucial role in protecting vulnerable tile corners from chipping, providing smooth transitions between surfaces, and elevating the overall aesthetic of spaces such as kitchens, bathrooms, and accent walls. Whether you're tiling a backsplash or outlining a shower enclosure, choosing the right material ensures longevity and visual appeal. This guide dives deep into the top contenders—aluminum, PVC, and stainless steel—drawing from industry standards and practical applications to help you make an informed decision.

The Importance of Quality Wall Tile Trim Edging

Before exploring specifics, it's essential to understand why wall tile trim edging matters. Exposed tile edges are prone to damage from daily wear, moisture, and impacts, leading to cracks or an unfinished look that detracts from your design. High-quality edging not only safeguards these areas but also creates clean lines that make rooms feel more spacious and modern. Factors like humidity levels, foot traffic, and style preferences heavily influence your choice. For instance, in humid environments, corrosion resistance is non-negotiable, while budget-conscious projects might favor affordability over premium shine.

Based on extensive reviews of installation guides and material analyses, the three most popular options—aluminum wall tile trim edging, PVC tile edging, and stainless steel tile trim—stand out for their balance of functionality and style. Each brings unique strengths, but none is flawless, creating opportunities for thoughtful tile trim comparison. Let's break them down.

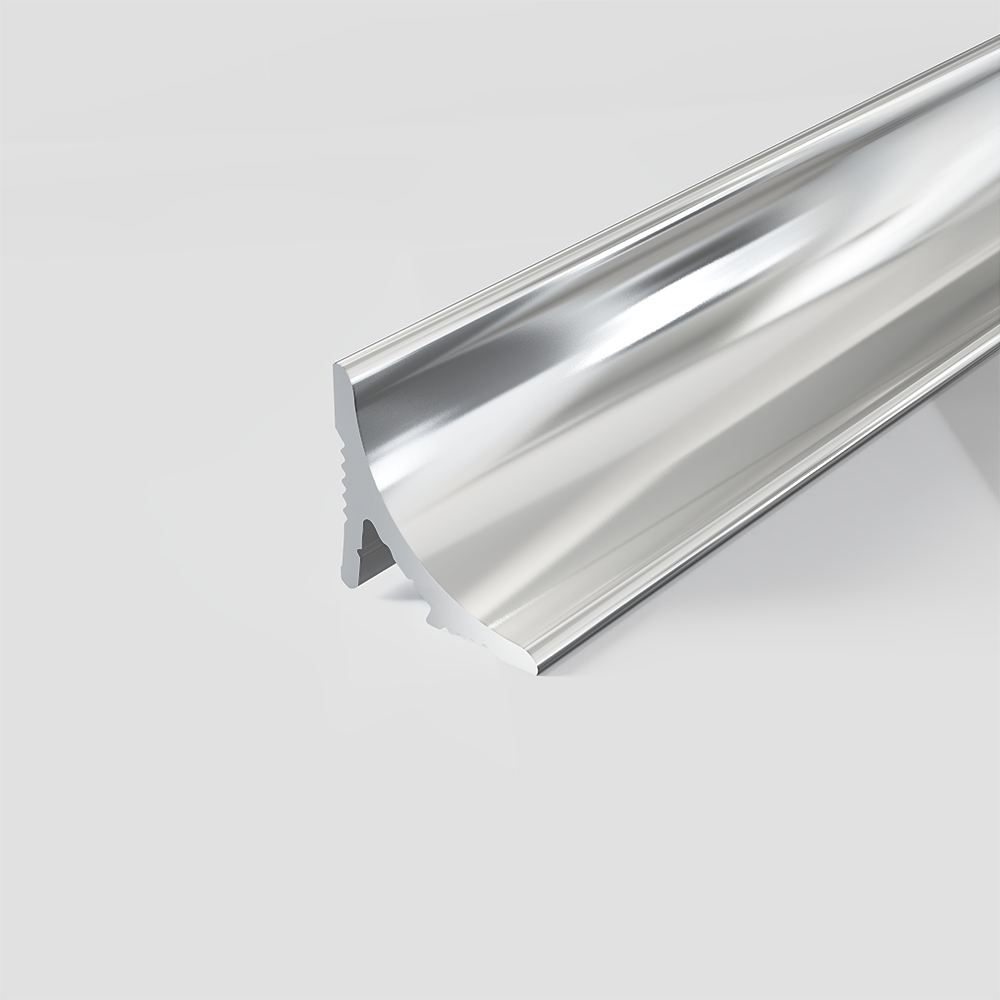

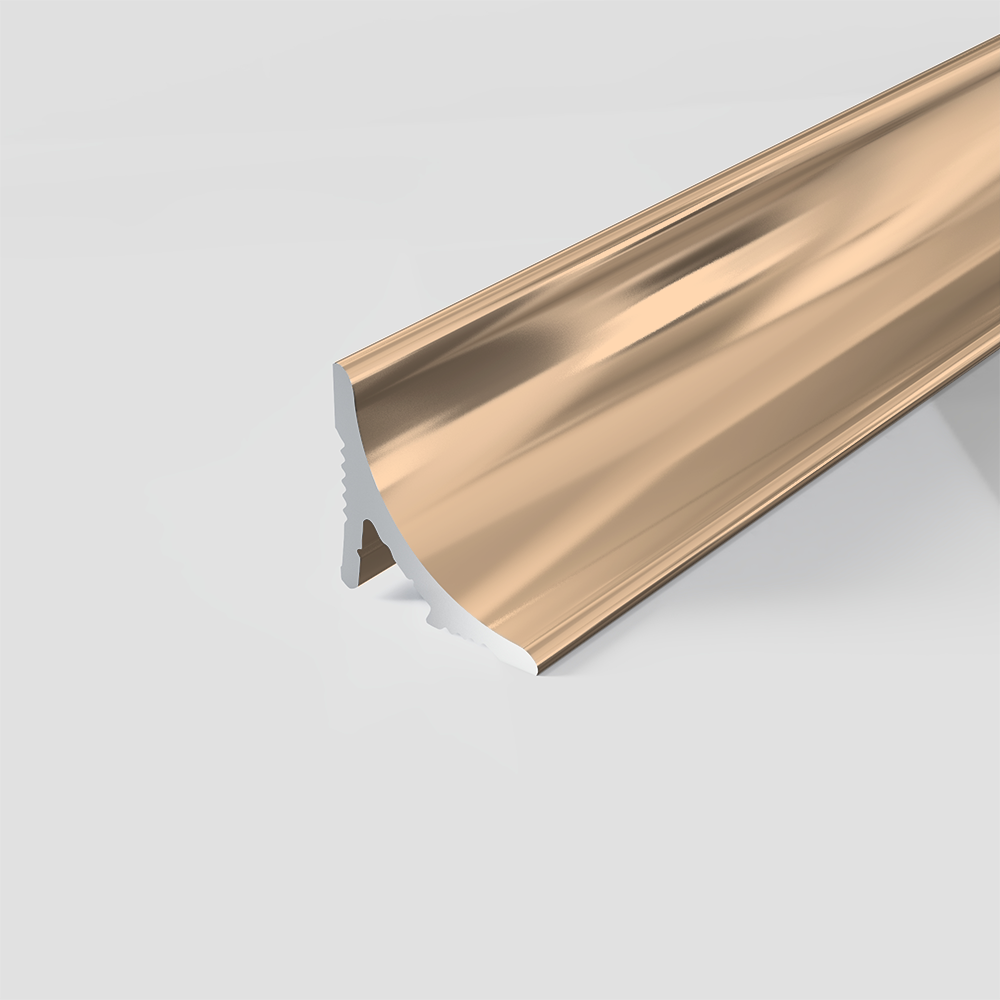

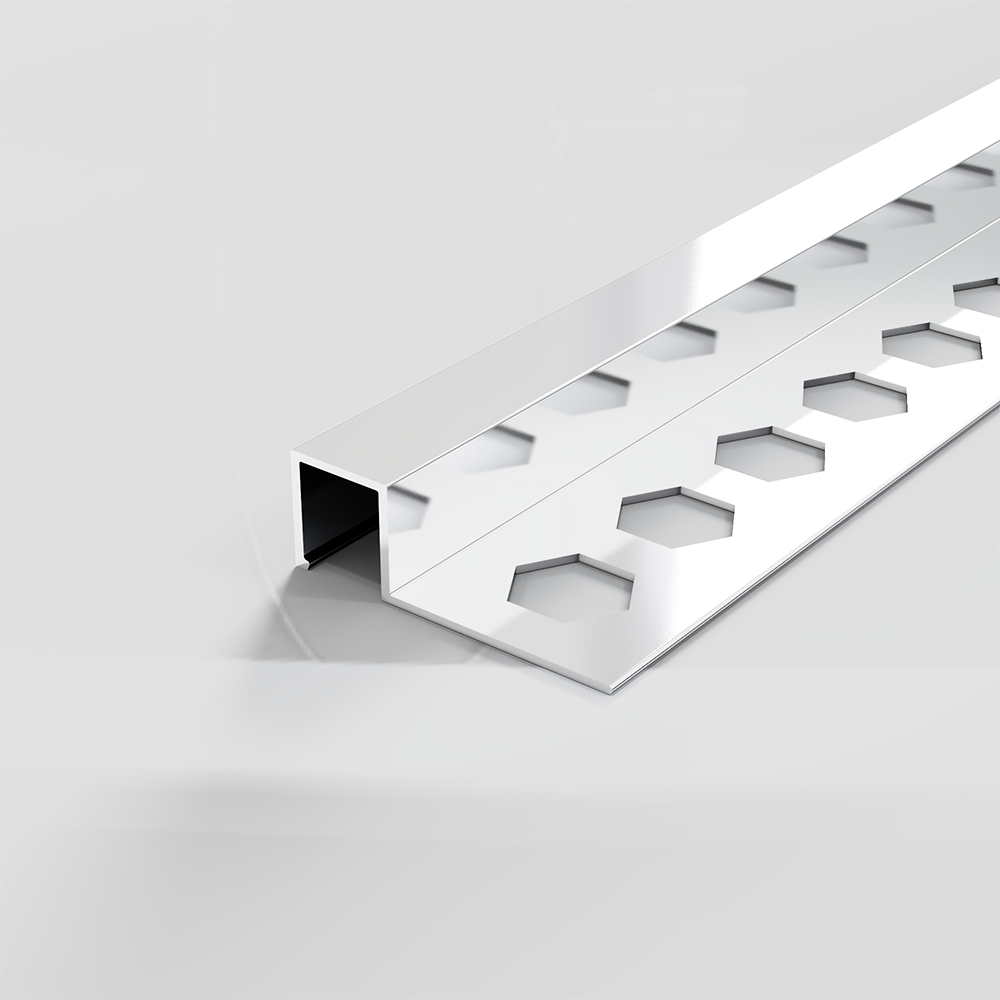

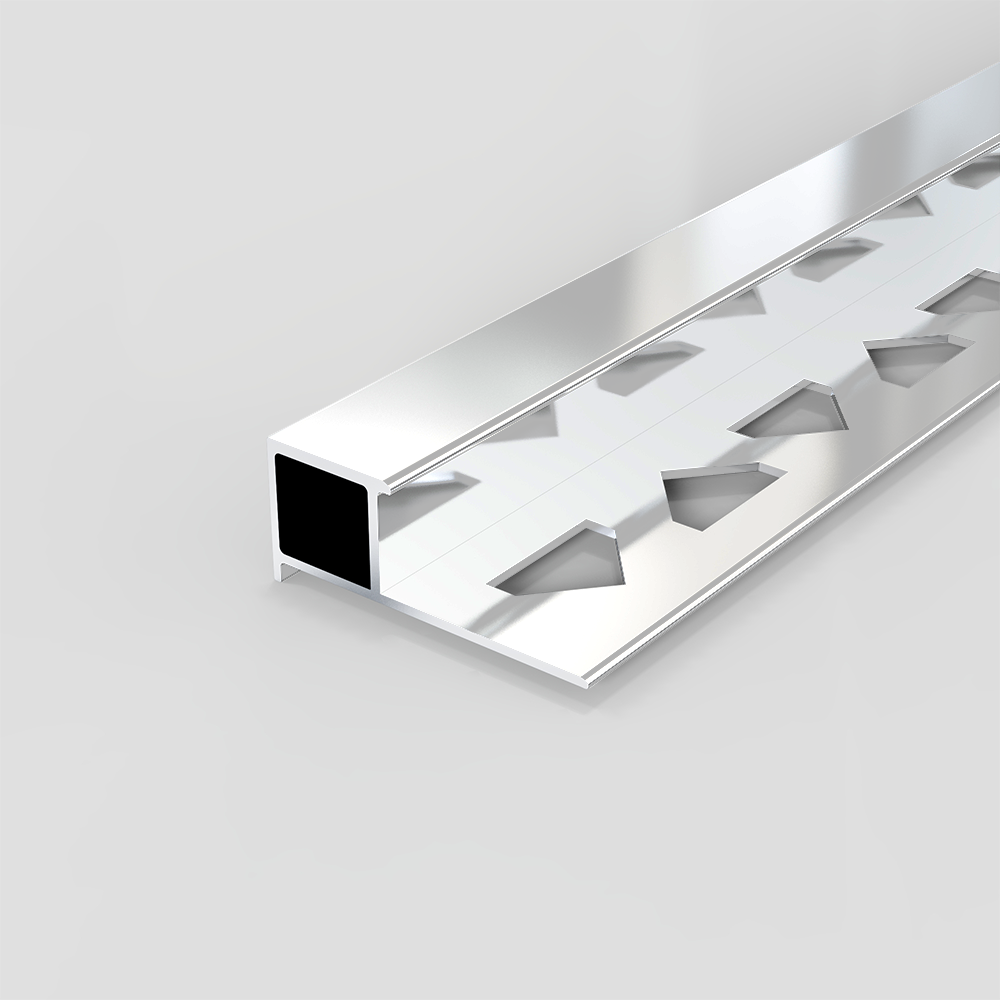

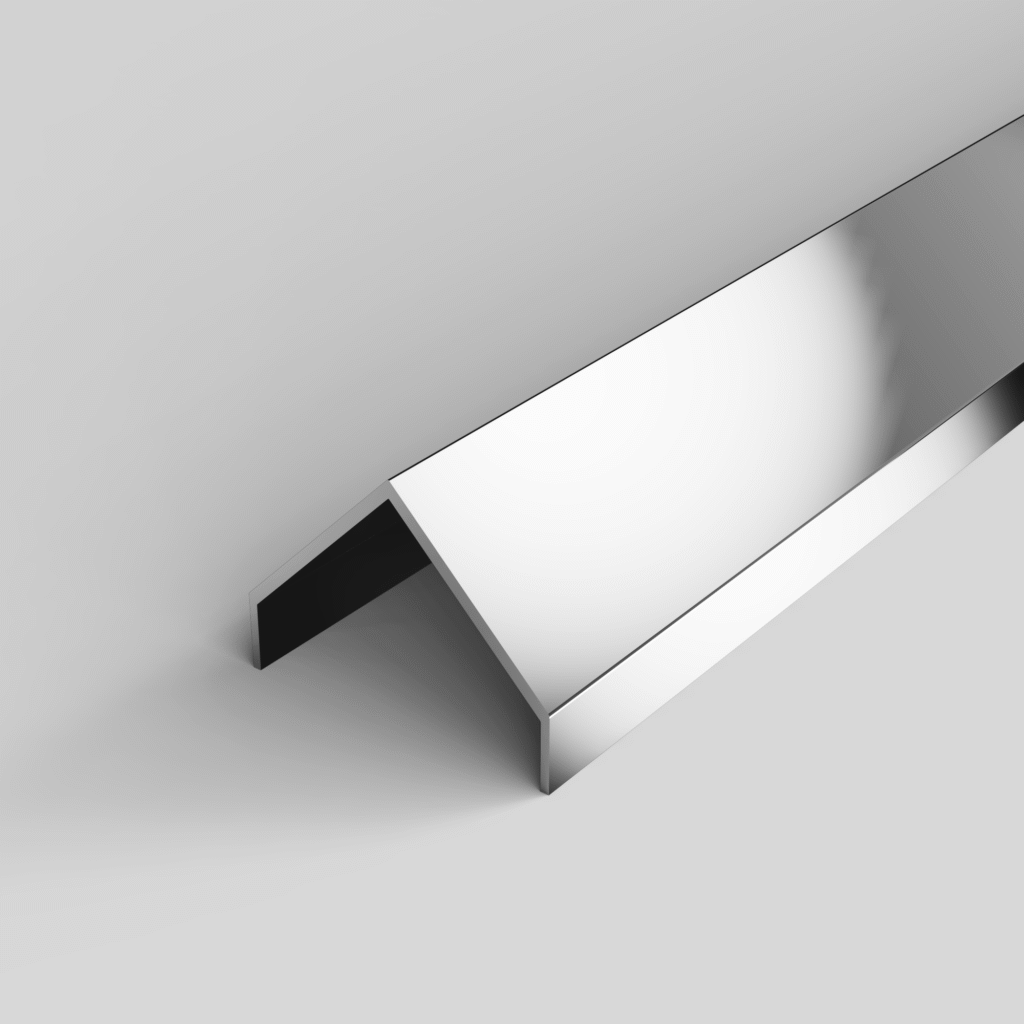

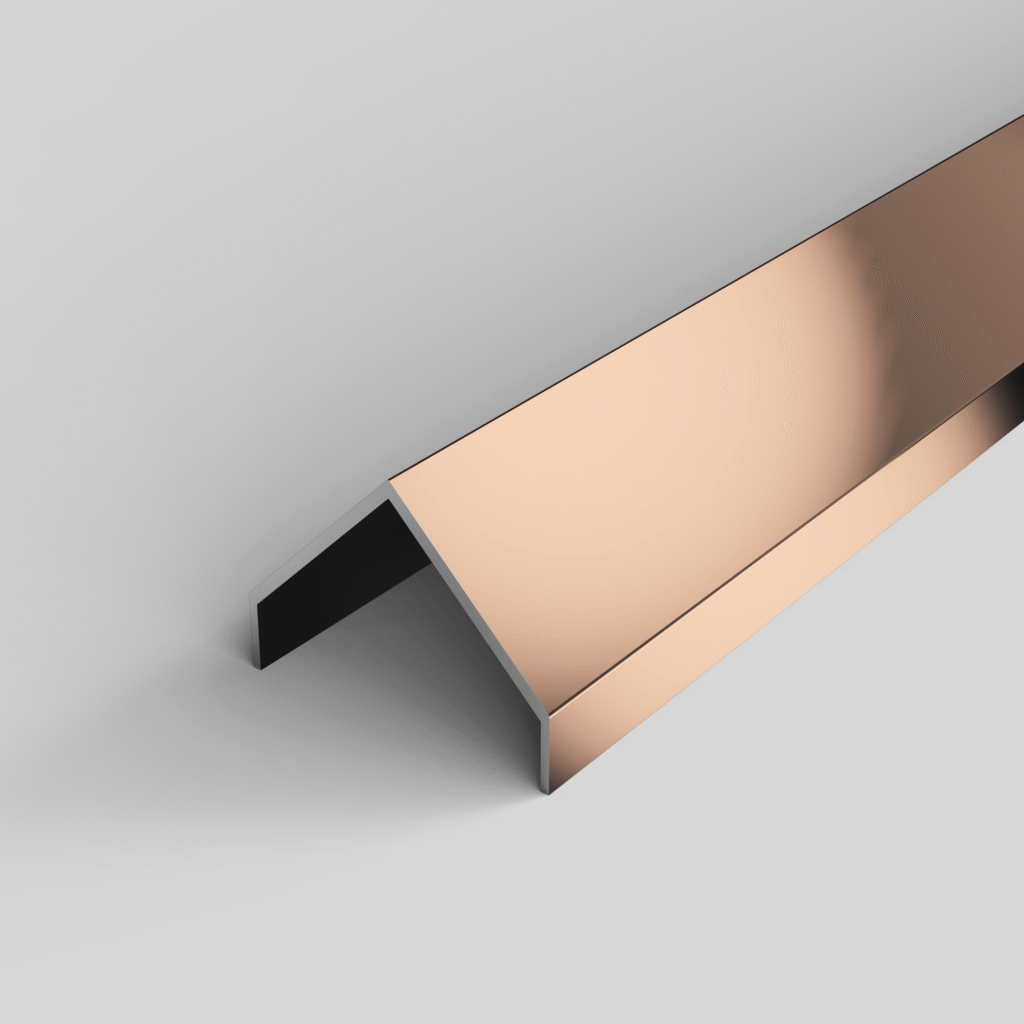

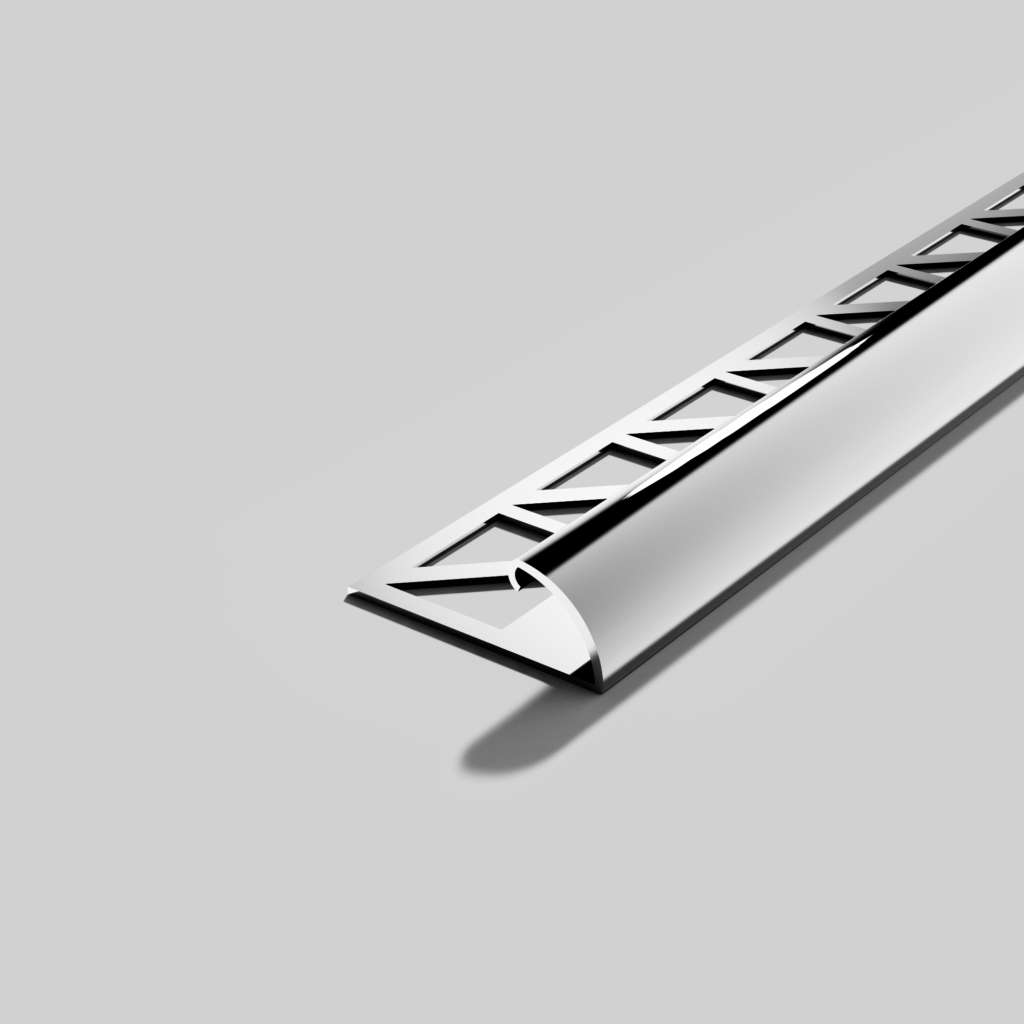

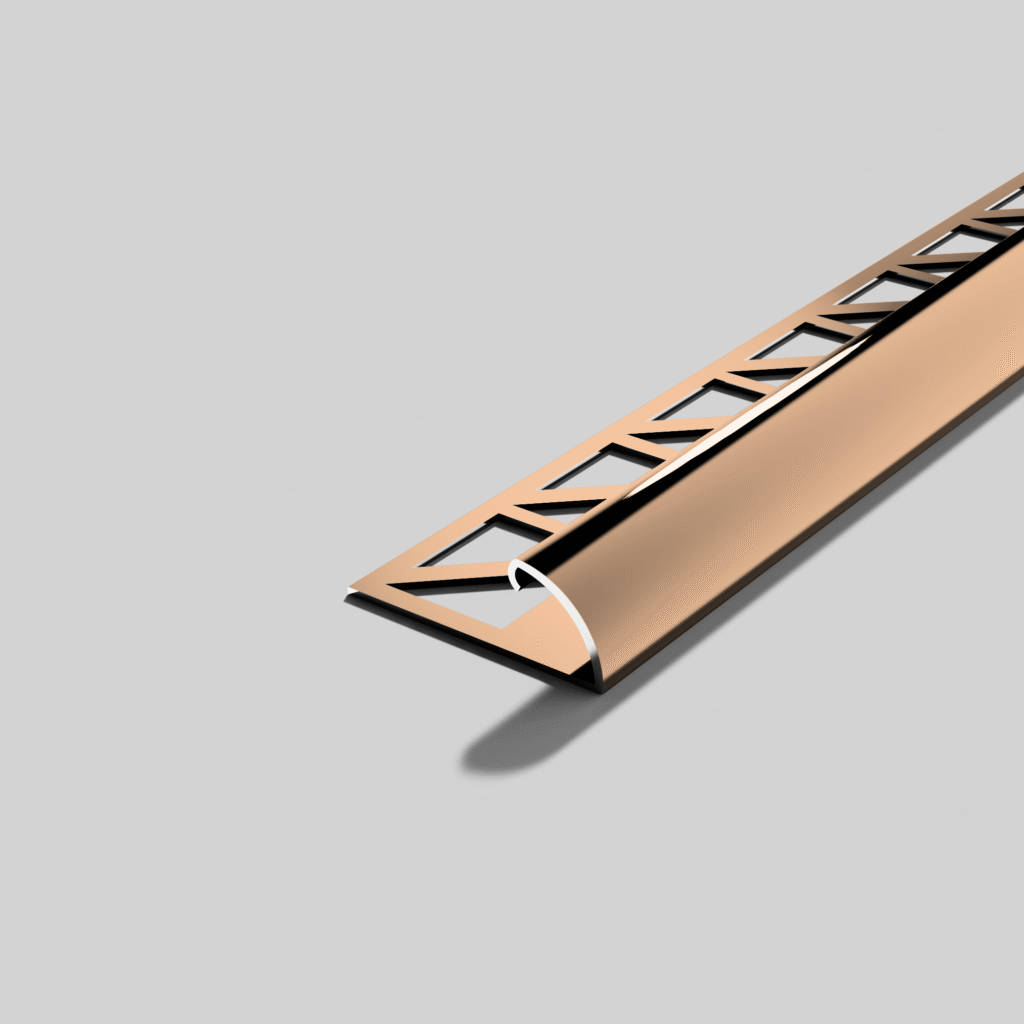

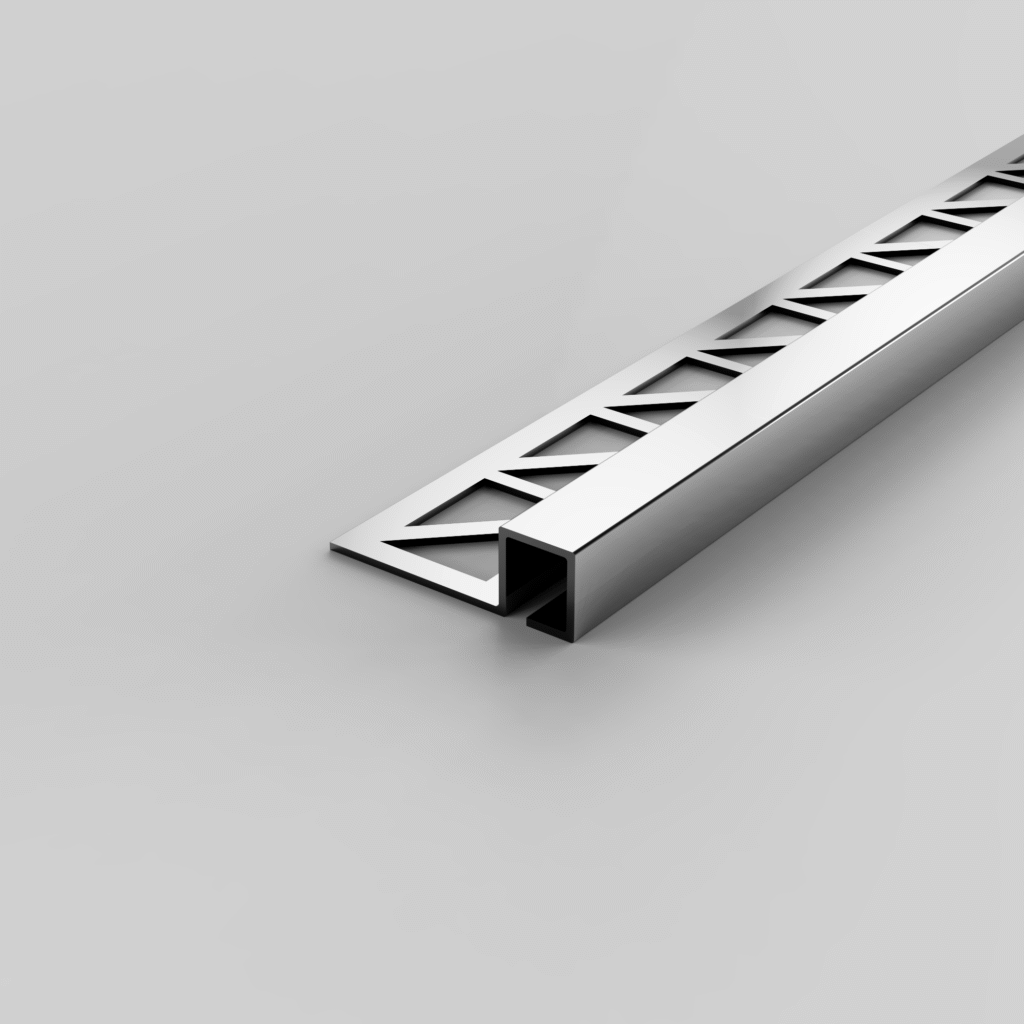

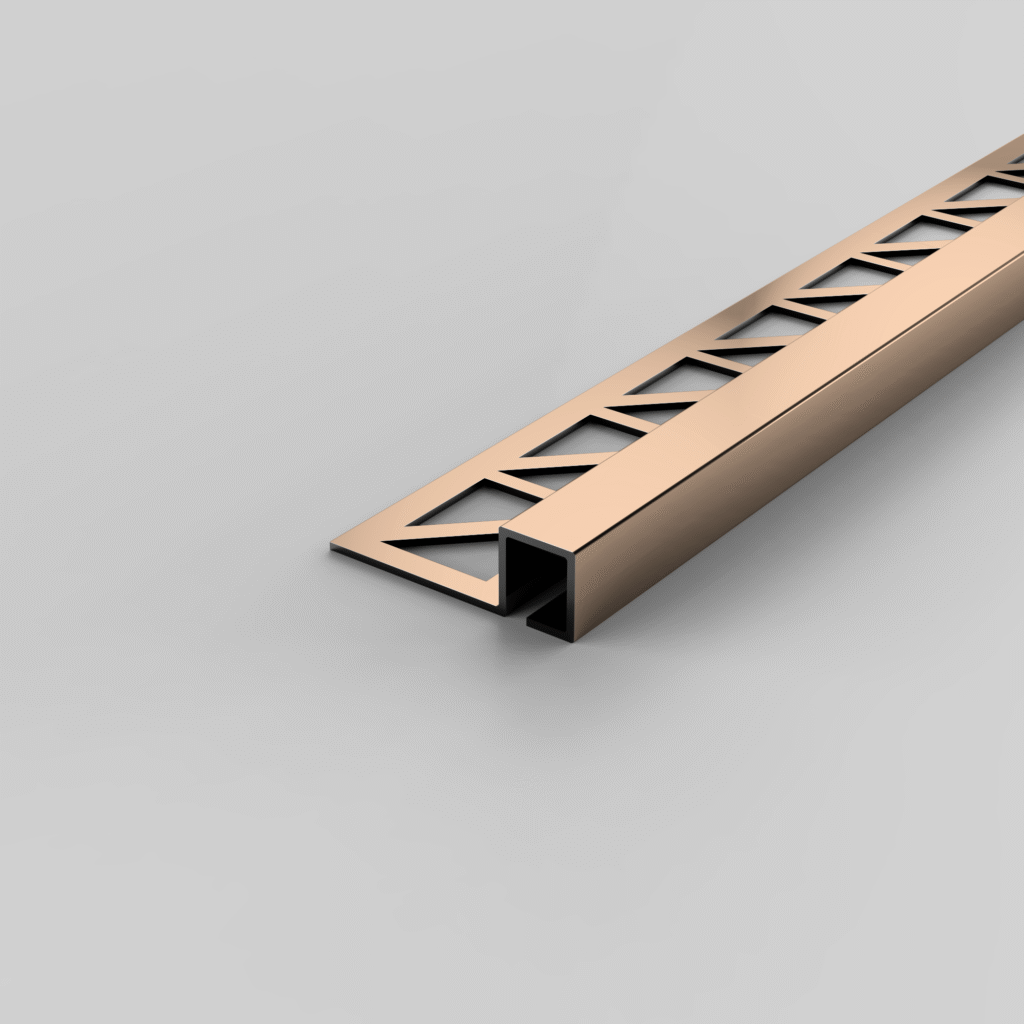

Aluminum Wall Tile Trim Edging: Lightweight and Versatile

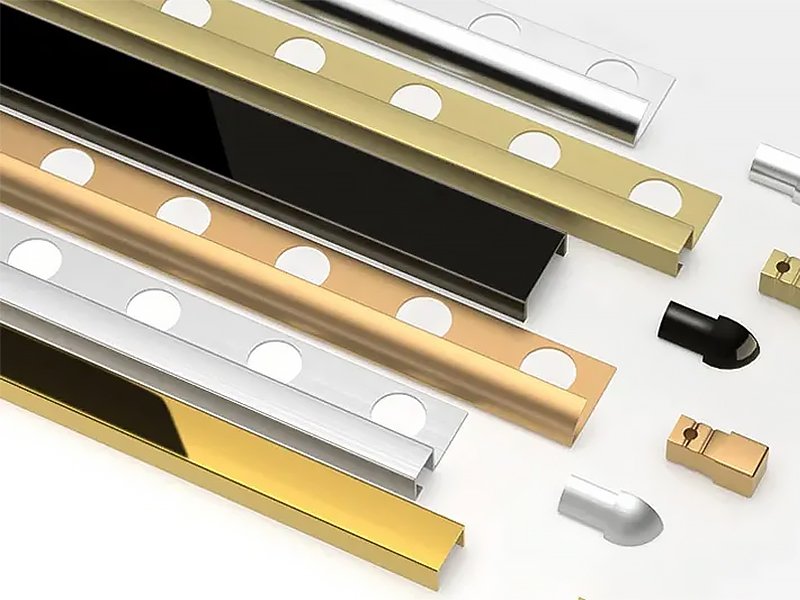

Aluminum emerges as a go-to for wall tile trim edging due to its featherlight weight and adaptability, making it a favorite for DIY enthusiasts and professionals alike. Anodized or powder-coated finishes resist fading and complement a range of tile colors, from subway whites to slate grays.

Pros:

- Corrosion Resistance:Ideal for moisture-prone areas like kitchens or laundry rooms, as it won't rust or tarnish easily.

- Ease of Handling:At just a fraction of the weight of steel, it's simple to cut, bend, and install without specialized tools—perfect for curved edges or overhead work.

- Aesthetic Flexibility:Available in brushed, polished, or colored variants, it adds a contemporary edge that blends seamlessly with minimalist or industrial designs.

- Cost-Effectiveness:Generally mid-range pricing allows for generous use without breaking the bank.

Cons:

- Moderate Durability:While tough against everyday bumps, it can dent or scratch in high-traffic zones, requiring occasional touch-ups.

- Environmental Sensitivity:Avoid prolonged outdoor exposure, as UV rays might cause subtle discoloration over years.

Aluminum shines in residential settings where best edging materials prioritize ease and style over industrial-grade toughness. For a tile trim comparison, it's often the "Goldilocks" option—not too heavy, not too fragile.

PVC Tile Edging: Budget-Friendly and User-Friendly

For those seeking an accessible entry into wall tile trim edging, PVC (polyvinyl chloride) delivers on affordability and simplicity. This plastic-based material mimics metal profiles at a fraction of the cost, making it a staple for quick renovations or rental updates.

Pros:

- Waterproof Excellence:Fully impervious to moisture, it's a safe bet for steamy bathrooms or splash-prone counters, preventing mold growth.

- DIY Simplicity:Self-adhesive backs and basic cutting tools mean installation takes minutes, not hours—great for beginners.

- Color Variety:Matches virtually any tile palette, from bold hues to neutrals, without custom orders.

- Low Upfront Investment:The most economical choice, allowing you to allocate funds elsewhere in your project.

Cons:

- Limited Longevity:Over time, it may yellow, crack under impact, or warp in extreme heat, shortening its lifespan compared to metals.

- Basic Appearance:Lacks the luxurious sheen of aluminum wall tile trim or stainless steel tile trim, potentially feeling less premium in upscale spaces.

PVC excels as a best edging material for low-stakes applications, like temporary backsplashes or child-friendly zones. In a head-to-head tile trim comparison, it wins on wallet-friendliness but lags in endurance.

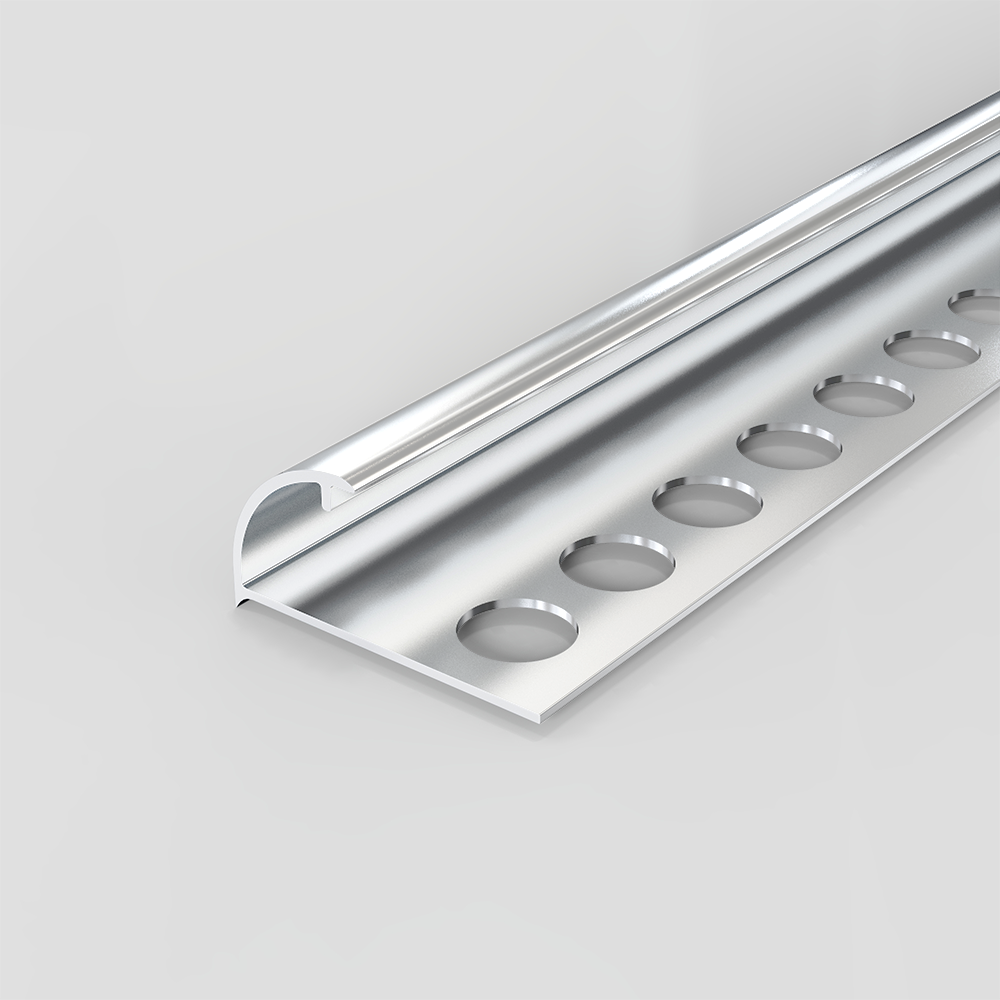

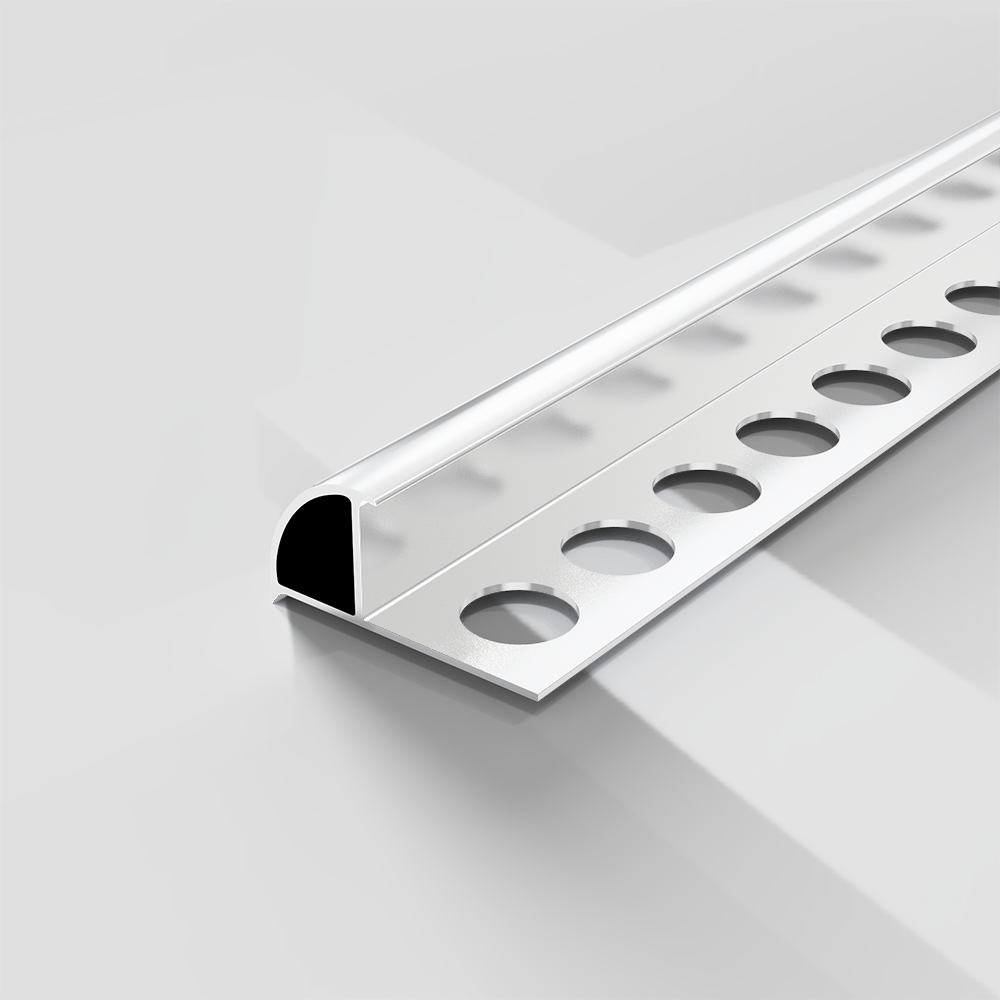

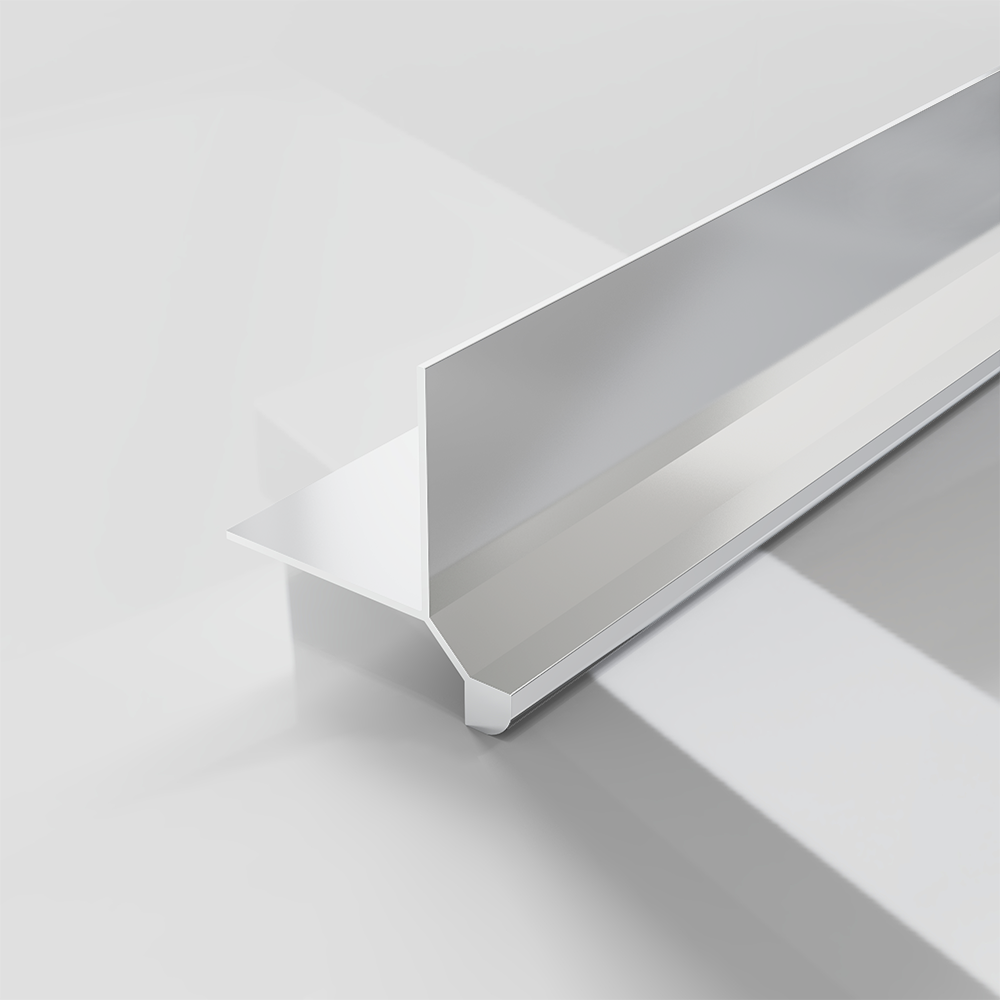

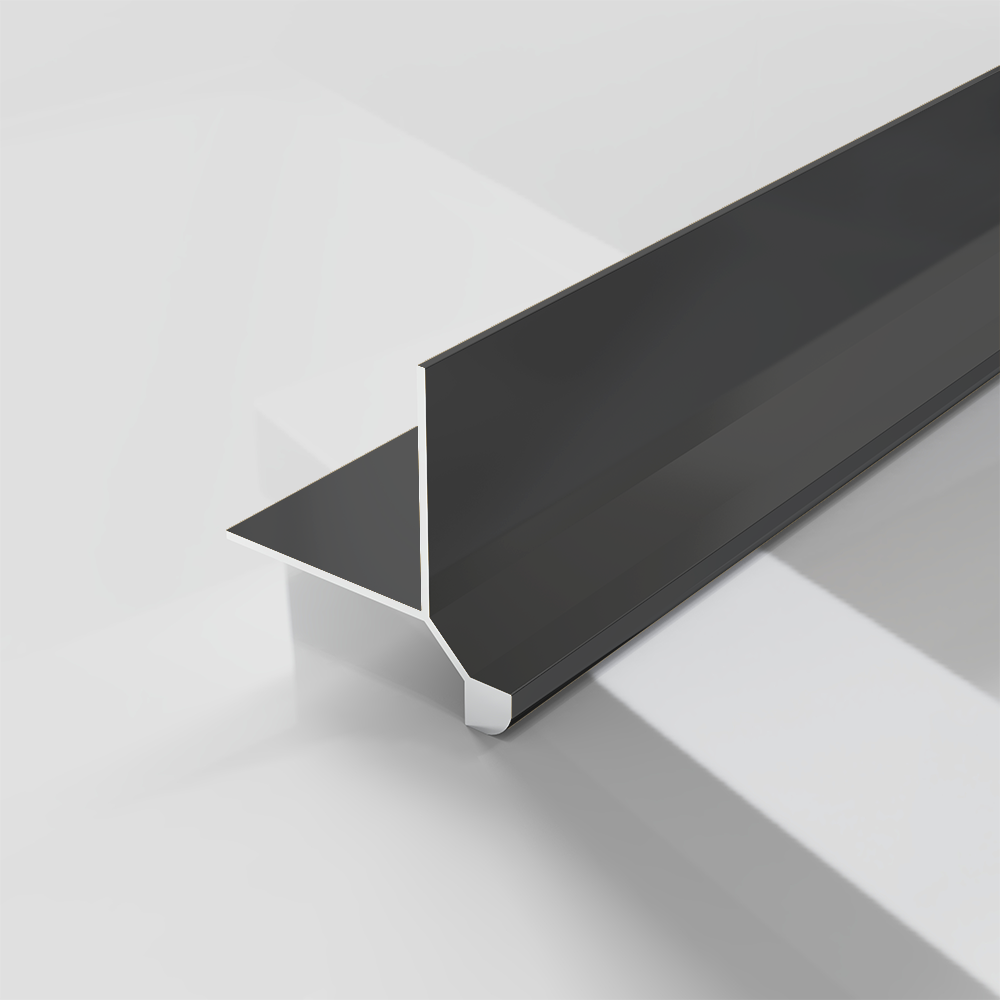

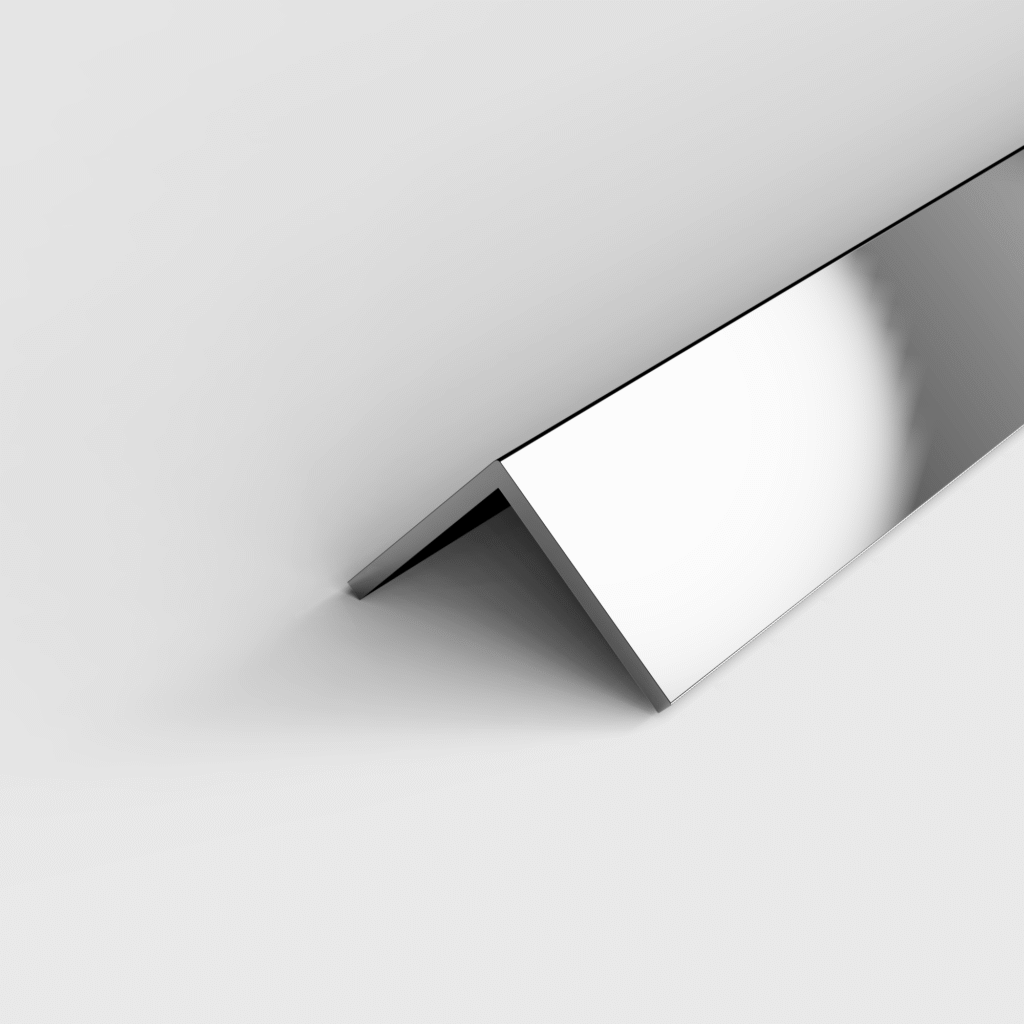

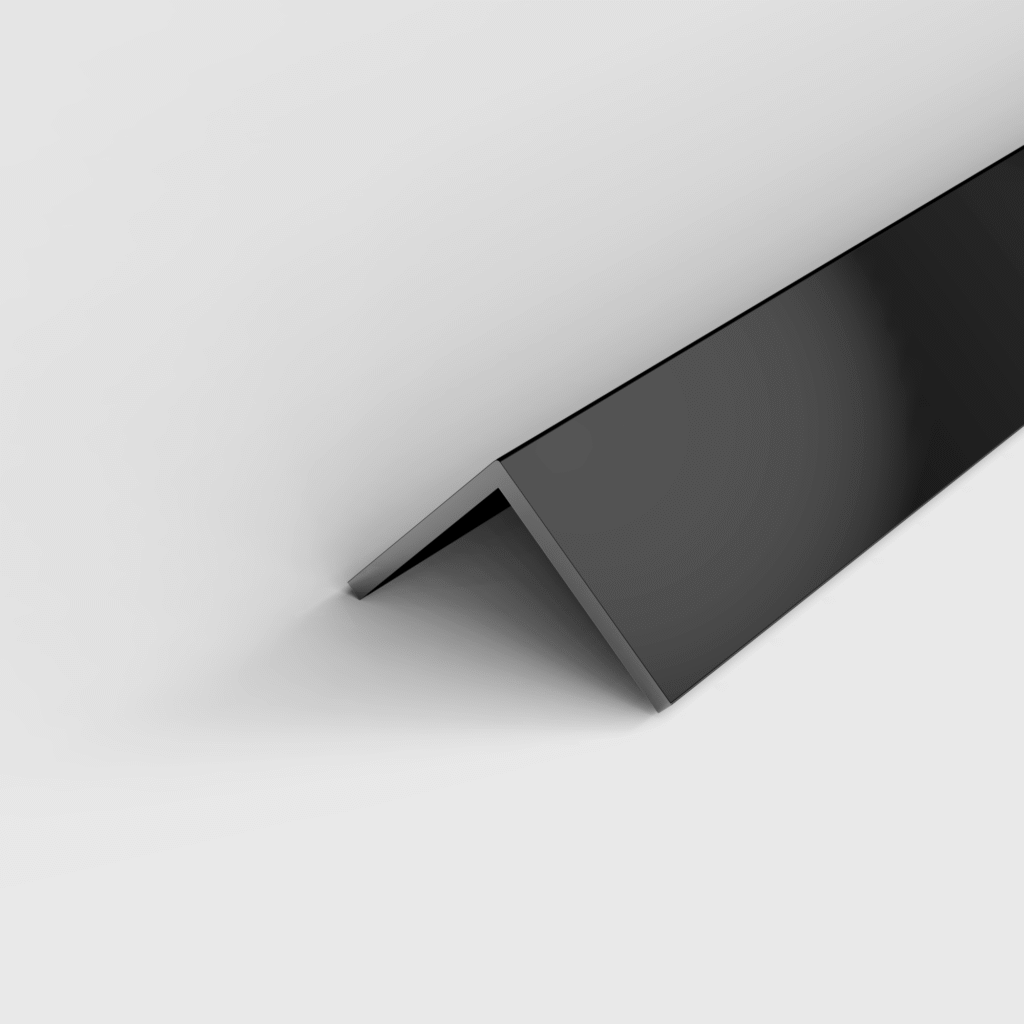

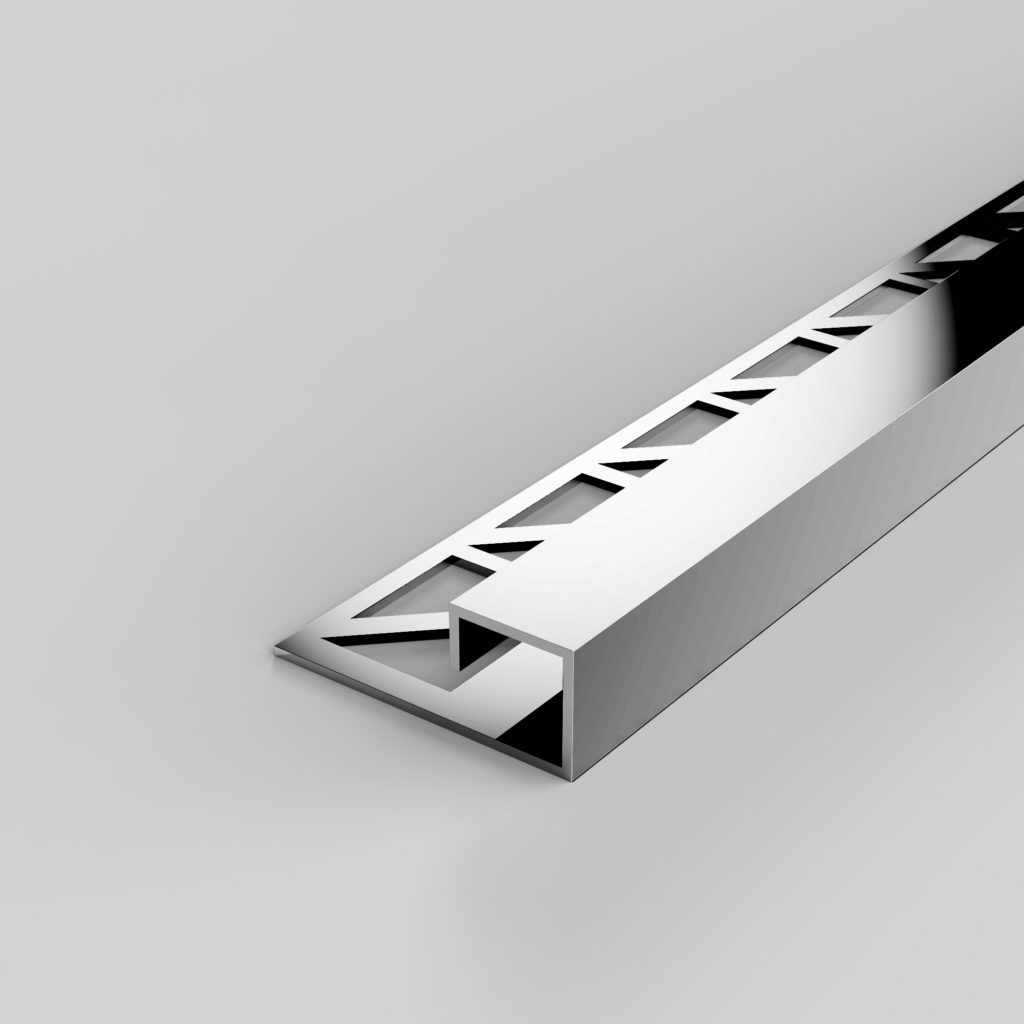

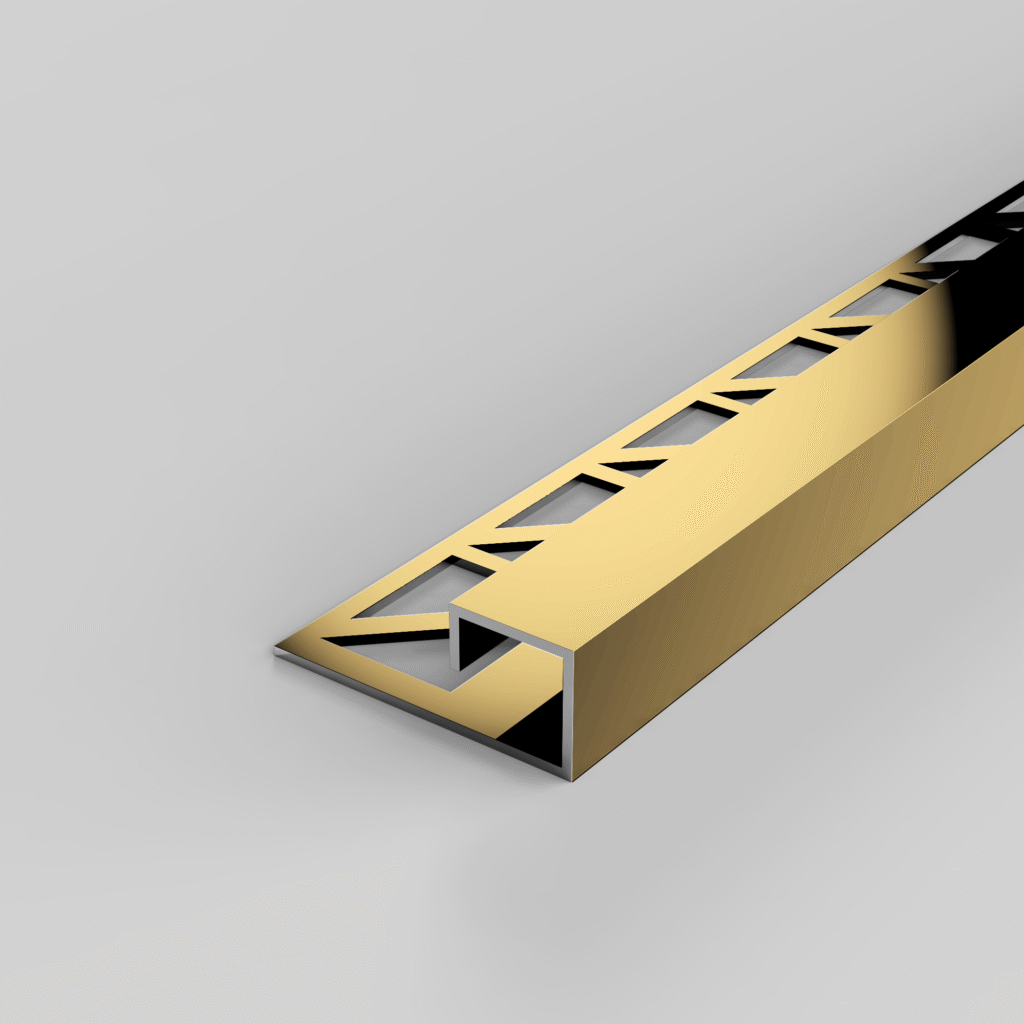

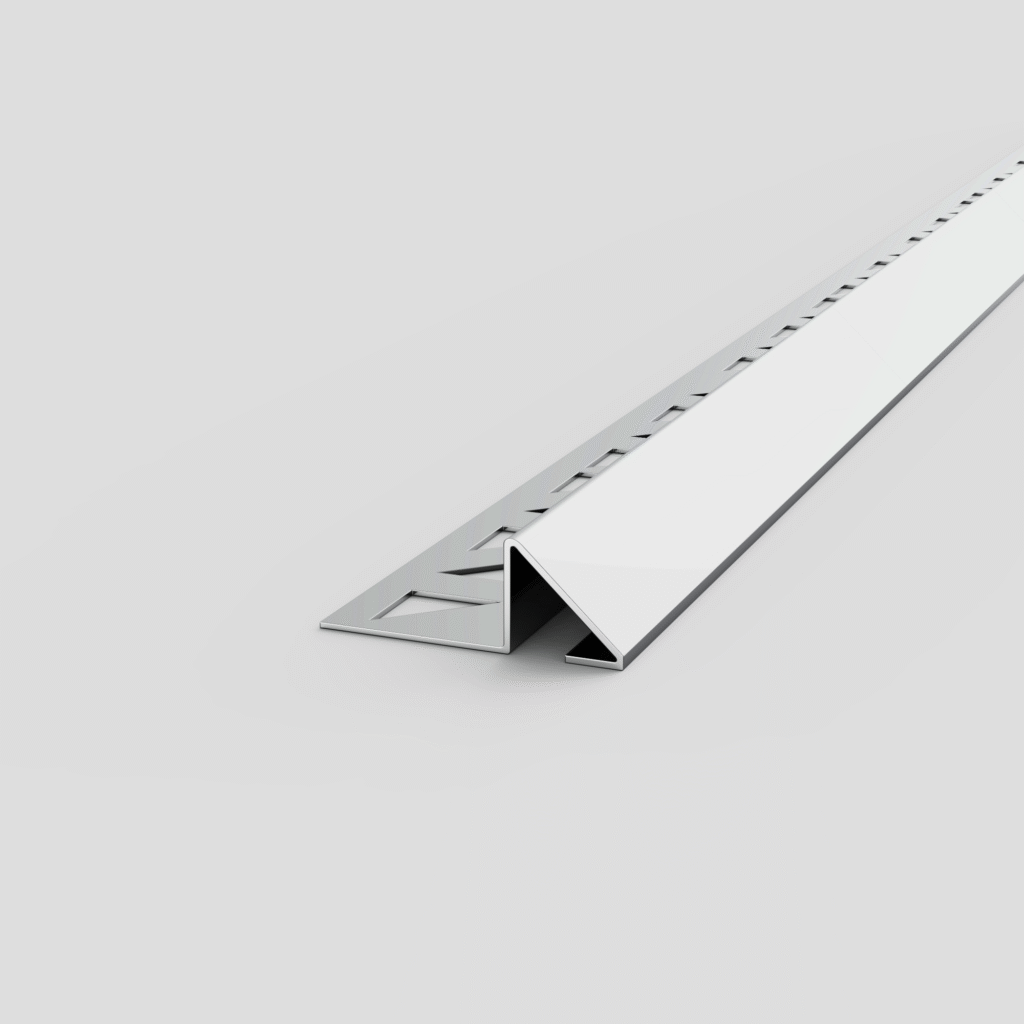

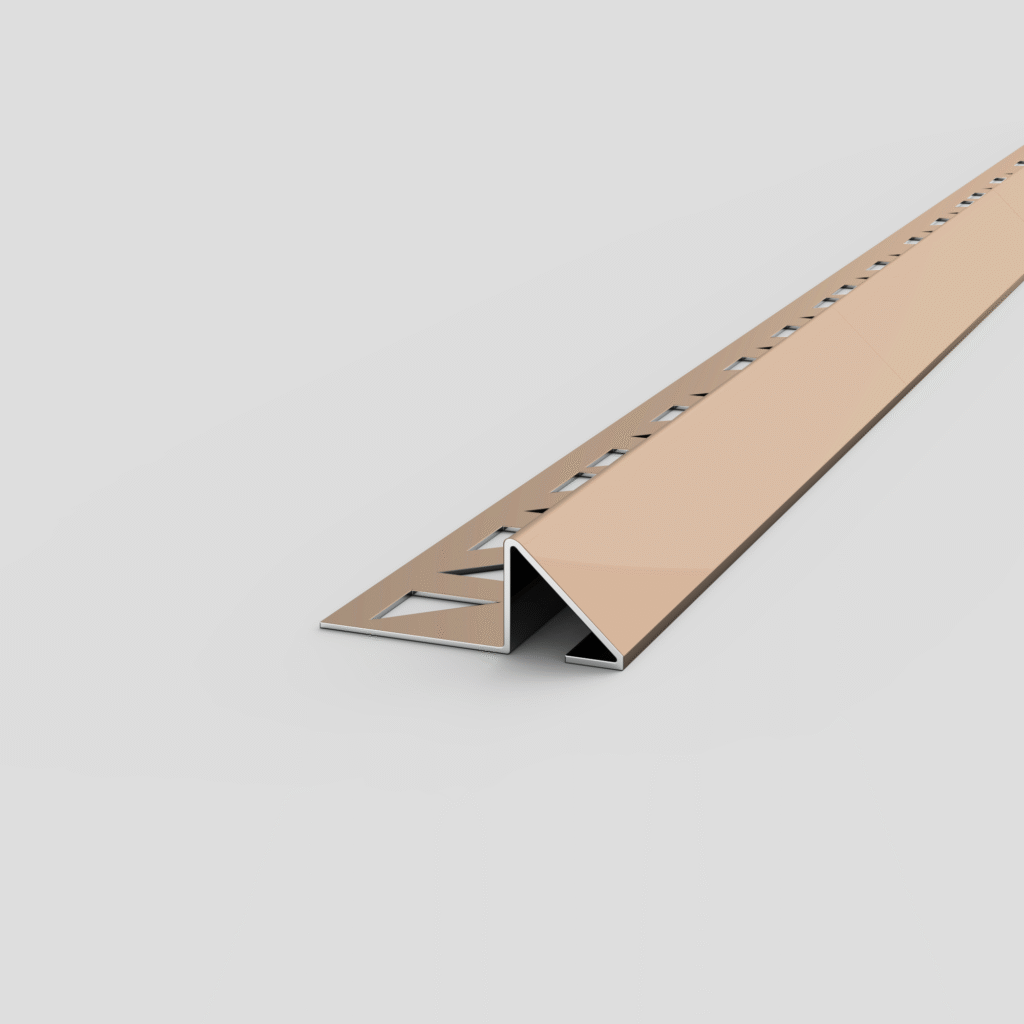

Stainless Steel Tile Trim: The Durable Powerhouse

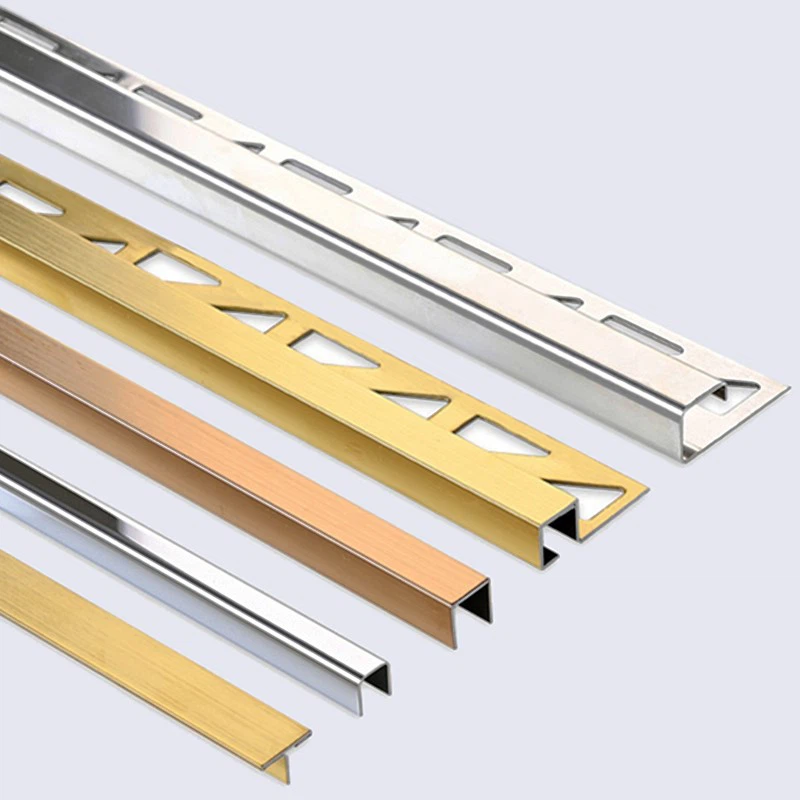

When premium performance is paramount, stainless steel tile trim takes the crown for wall tile trim edging. Its robust construction and timeless appeal make it a staple in commercial and high-end residential projects, where reliability trumps all.

Pros:

- Unmatched Strength:Resists dents, scratches, and heavy impacts, ensuring your edges stay pristine for decades.

- Superior Corrosion Protection:Grade 304 or 316 variants thrive in chlorinated pools, salty coastal homes, or acidic kitchens without pitting.

- Elegant Finish:Brushed or mirrored surfaces add a sophisticated gleam that enhances any tile—from glossy porcelain to matte stone.

- Low Maintenance:A quick wipe with soapy water keeps it spotless, with no fading or staining worries.

Cons:

- Higher Price Tag:The investment is steeper, which might strain smaller budgets despite long-term savings on replacements.

- Installation Precision:Harder to cut and shape, often needing power tools or pros to avoid jagged edges.

For demanding environments, stainless steel is the undisputed leader in tile trim comparison, offering peace of mind that best edging materials should provide.

In-Depth Tile Trim Comparison: Side-by-Side Analysis

To simplify your decision, here's an expanded tile trim comparison table evaluating key attributes across aluminum, PVC, and stainless steel wall tile trim edging. This draws from practical testing and user feedback, highlighting how each performs in real-world scenarios.

Attribute | Aluminum Wall Tile Trim | PVC Tile Edging | Stainless Steel Tile Trim |

Durability Rating (1-10) | 7 (Good for indoors; bends under force) | 5 (Handles light use; cracks with impacts) | 9 (Excels in all conditions) |

Cost per Linear Foot | $2–$5 (Balanced value) | $1–$3 (Most economical) | $4–$8 (Premium pricing) |

Moisture Resistance | High (Anodized coatings prevent rust) | Excellent (Fully waterproof) | Exceptional (Chemical-proof grades available) |

Aesthetic Appeal | Versatile modern looks (brushed/polished) | Customizable colors but plastic sheen | Luxurious, reflective finishes |

Installation Time | 20–30 min per section (Light and flexible) | 10–15 min per section (Adhesive ease) | 30–45 min per section (Requires precision tools) |

Maintenance Needs | Low (Occasional polishing) | Minimal (Wipe clean) | Very low (Resists stains effortlessly) |

Lifespan (Years) | 10–15 (With proper care) | 5–10 (Fades in sun/heat) | 20+ (Virtually indestructible) |

Eco-Friendliness | Recyclable; lightweight reduces transport emissions | Non-toxic but plastic-based | Highly recyclable; durable minimizes waste |

This table underscores the trade-offs: PVC for quick wins, aluminum for everyday balance, and stainless steel for legacy builds. Metrics like durability are averaged from installation reports, showing stainless steel's edge in longevity.

How to Choose the Right Wall Tile Trim Edging for Your Project

Selecting among these best edging materials involves more than specs—consider your space's demands. For wall applications in dry areas like living rooms, aluminum's lightness prevents sagging. In wet zones, prioritize PVC's waterproofing or stainless steel's resilience. Budget plays a role too: Start with PVC for prototypes, then upgrade to metals for finals. Always measure twice—trim widths should match tile thickness (typically 1/8–1/4 inch) for flush fits. Test samples against your tiles under room lighting to ensure harmony.

Installation tips: Clean surfaces thoroughly, use thin-set mortar or adhesive, and caulk joints for waterproof seals. For curves, opt for flexible variants like PVC. Professional installers recommend pre-cutting pieces to minimize waste.

Emerging Trends and Expert Insights

Recent innovations in wall tile trim edging include hybrid composites blending PVC's ease with aluminum's strength, though they're pricier. Sustainability is rising—recycled aluminum options reduce environmental impact without sacrificing quality. Experts from tile associations emphasize matching trim to tile modulus (flexibility) to avoid cracks during settling. In high-contrast designs, stainless steel's gleam creates focal points, while PVC's subtlety recedes for monochromatic looks.

Conclusion: Elevate Your Edges with Confidence

Ultimately, the "best" wall tile trim edging aligns with your priorities—aluminum for versatile charm, PVC for accessible functionality, or stainless steel for unbeatable endurance. By weighing a thorough tile trim comparison, you'll craft edges that not only protect but also inspire. Ready to transform your space? Source from reputable suppliers and dive into your project with these insights as your guide.

Our Products

Latest Articles

Get A Free Sample

Try out the products you are interested in and get free samples. See the quality for yourself and let’s start working together right away.

Get In Touch Today

After you fill out the form, We will contact you within 24 hours.

The first objective will be to understand your needs, then develop a business plan together and provide you with the best pricing!

Address

Workshop No. 3 (Self - designated), Sizhong Industrial Zone, Dazhen Community, Dali Town, Nanhai District, Foshan City

Tel

+86 13392243769

+86 13392243769

senmry@vip.163.com